Custom Clean-

in-Place (CIP)

Systems

Designed for Your Application to Provide

Reliable, Consistent Cleaning

Custom Clean-In-Place (CIP) Systems

Designed for Your Application to Provide Reliable, Consistent Cleaning

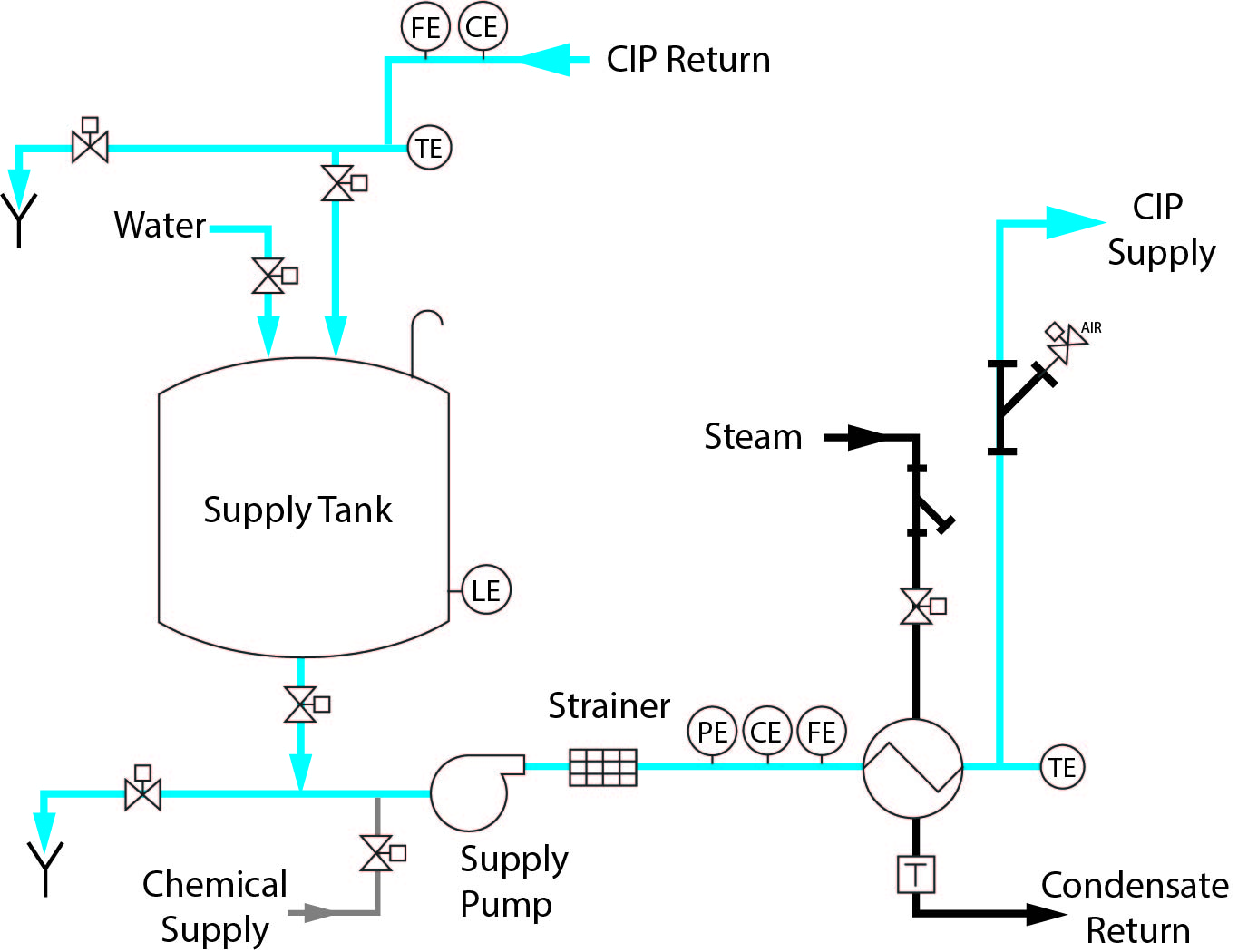

Sani-Matic CIP Systems are engineered to your specific plant application, layout and utility requirements for effective and efficient sanitary process equipment cleaning. Our application-specific CIP design and sizing ensures sufficient flow. As a result, appropriate pressure is available to thoroughly remove residue, rinse effectively, shorten cycle times and promote worker safety.

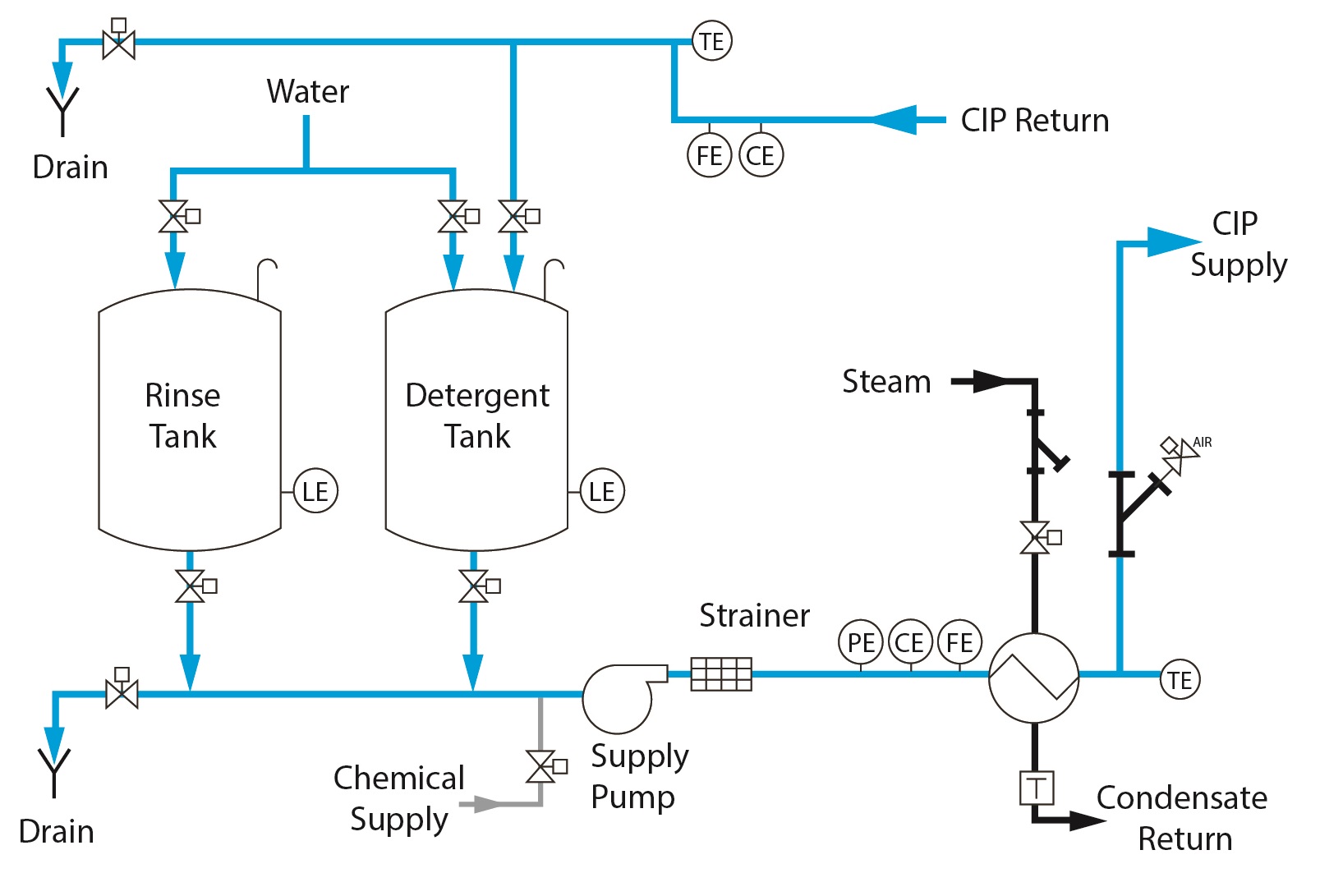

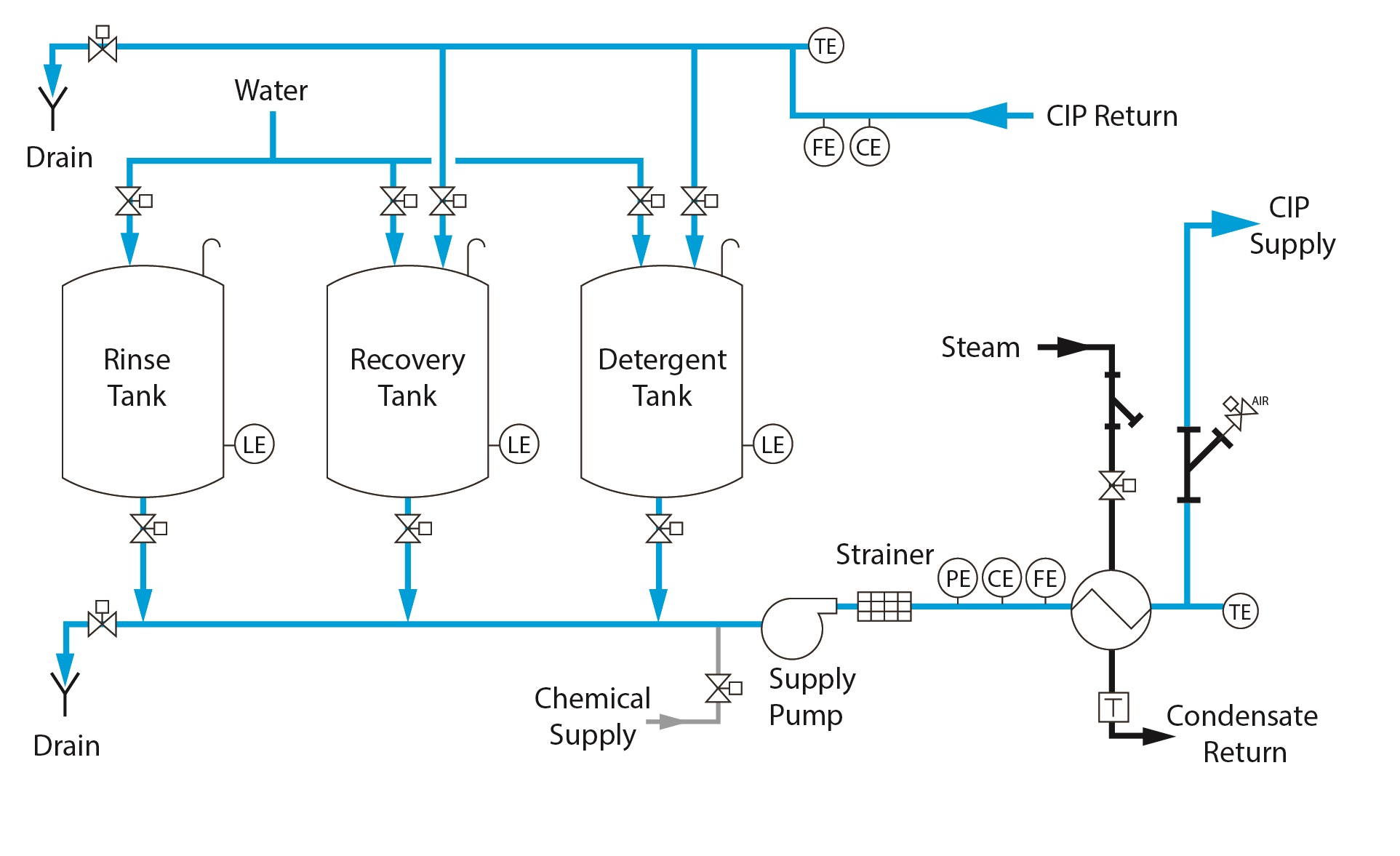

1 Tank CIP System options provides simple and small footprint solution. 2 Tank systems typically will be designed with one rinse tank and one wash tank, where wash solutions are re-used, saving chemical & utilities. 3 Tank systems often add a Rinse Recovery tank, where final rinse water is saved for future cycle pre-rinses, saving water. Additional tanks can be added for other chemical wash steps (e.g., Acid wash).

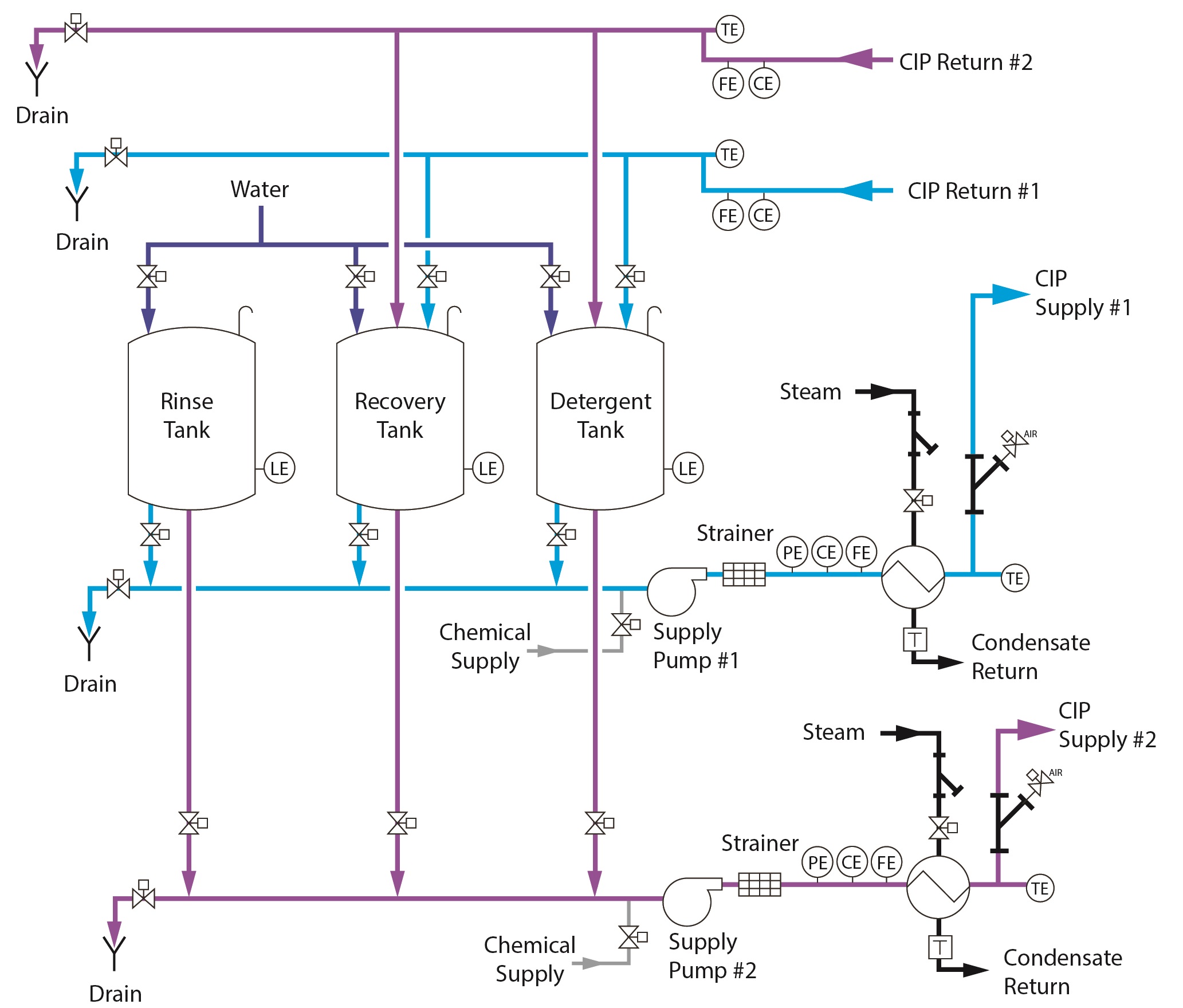

A Multi-Circuit CIP System is one system with multiple circuits and shared tanks. This design allows the system to clean multiple processes, the same as multiple single circuit CIP systems would, while providing significant space and cost savings—and cutting cleaning time by 50% for dual circuits systems.

Whichever system design is decided upon, our in-house automation programming experts design each CIP program to optimize cycle times that get you back into production faster, while reducing chemicals, water use and operating costs.

Sani-Matic CIP Systems—from single- to multi-tank or dual operating—are sanitary and can be engineered to 3-A standards.

Literature

View & download our latest manuals, technical datasheets, catalogs & more.

Articles

Read articles written by industry leaders to share their expertise and recommendations.

Product Resources

Literature

Videos

Product Details

CIP System Design Options

One-Tank Single Use

○ Single-use source of cleaning solution and rinse water

○ Lower capital investment

○ Portable or stationary design

○ Once-through or recirculated

○ Simple and flexible operation

○ Lower space requirement

Two-Tank Detergent Recovery/Reuse

○ Permits recovery and reuse of wash solution

○ Used where water utilities are limited

○ Supply/recirculation option

○ Decreases wash cycle time

Multi-Tank Detergent and Rinse Recovery/Reuse

○ Permits recovery and reuse of wash solution and rinse water

○ Reduces water and waste water costs

○ Fourth tank may be added for acid recovery and reuse applications

Multi-Circuit and Recovery/Reuse

○ Serves multiple circuits independently and simultaneously

○ Substantial cost and space-saving advantages over multiple separate units

○ Centralized controls

○ Reduced wash and rinse cycle times

How it Works

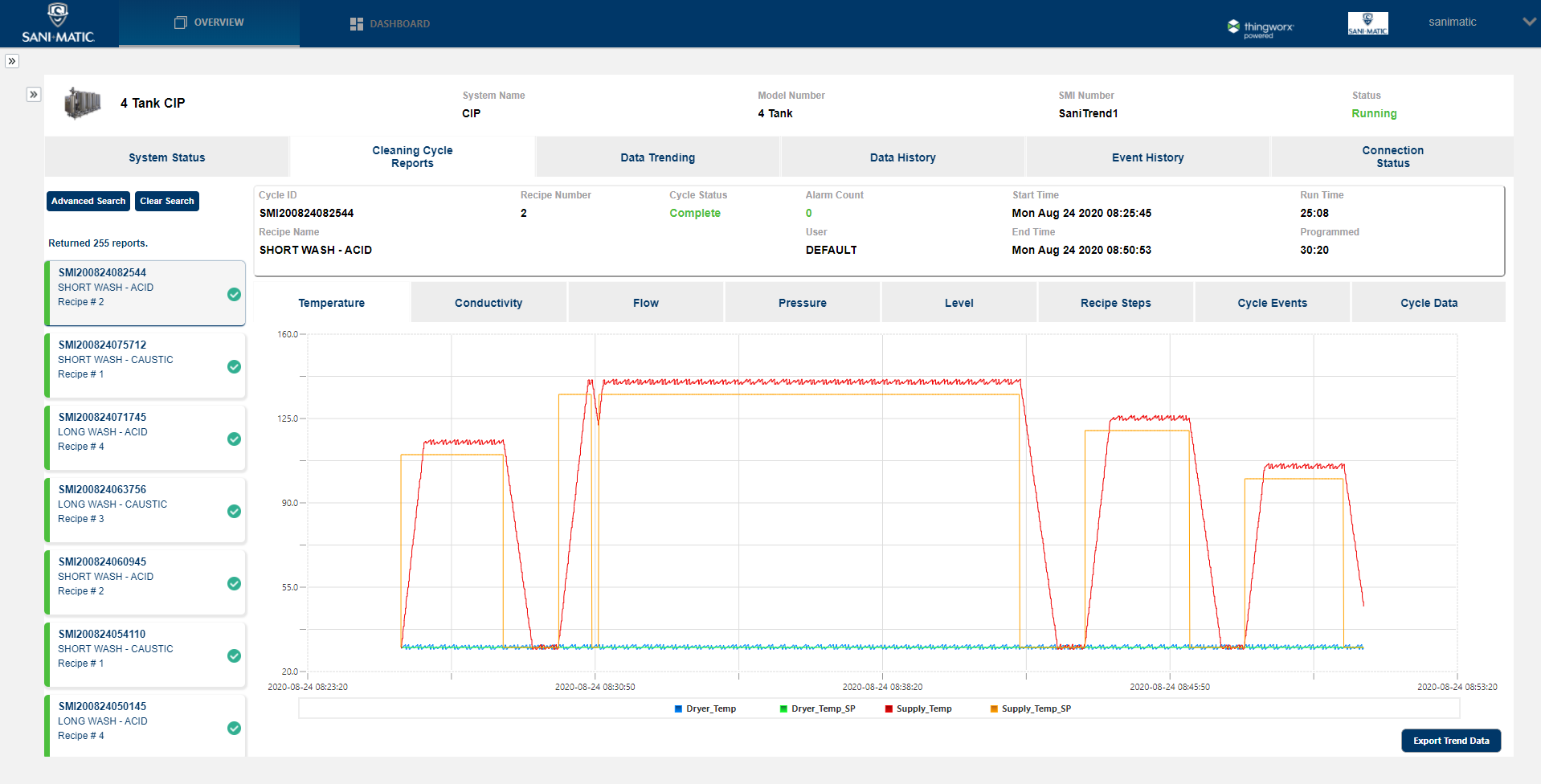

Automated Electronic CIP/COP

Data Recording, OEE, & More