Product Carrier

Washers

Rack Washers for a Complete Clean of Hard-

to-Clean Racks, Trees and Trucks

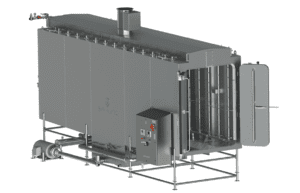

Product Carrier Washers

Rack Washers for a Complete Clean of Hard-to-Clean Racks, Trees and Trucks

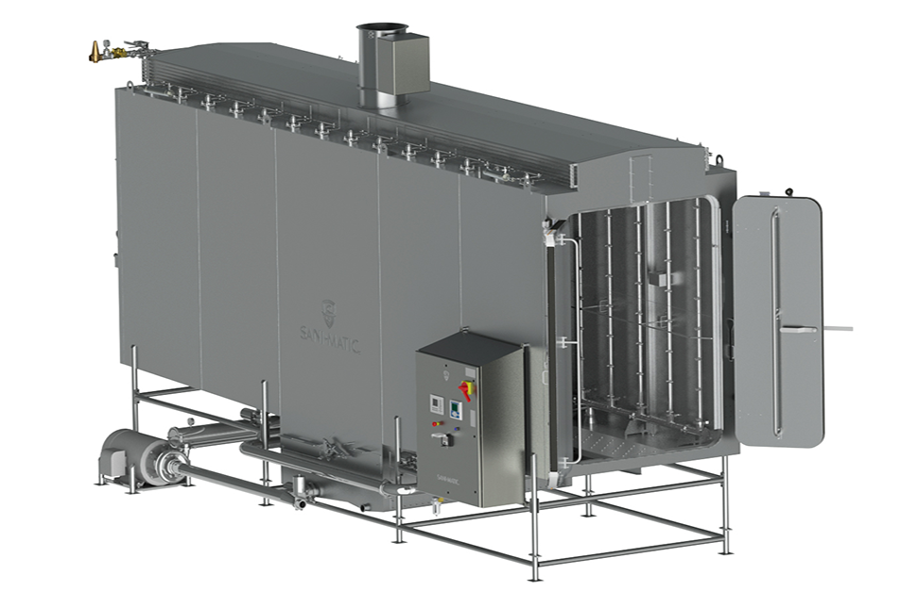

Sani-Matic Product Carrier Washers are engineered to clean product carriers such as racks, trees, cages and trucks using a consistent, cost-effective process. Our exclusively designed rotating spray arms and oscillating spray bars ensure cleaning solutions are evenly distributed inside the washer to tackle tough-to-clean, baked-on food product.

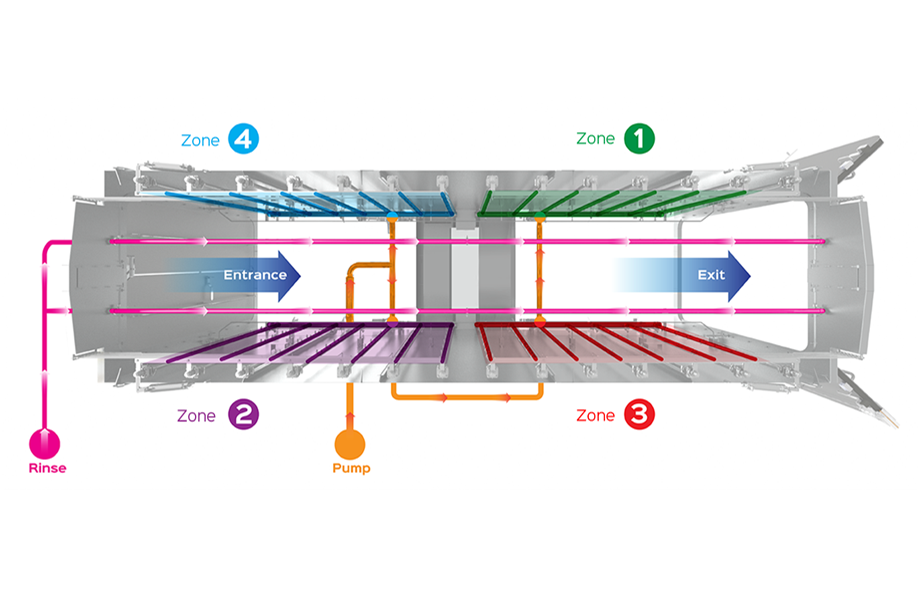

The Sani-Matic zoned sequence design provides a thorough clean:

Alternating zones generate higher impact spray coverage and eliminate interference from counter spray. Using a zoned pattern increases chemical dwell time to remove even the most difficult product residue, such as those found in smoked meat and bakery applications.

Sustainability and safety advantages are also found with the Product Carrier Washer:

Cleaning solutions are drawn from the reservoir and recirculated, reducing chemical and water use. The stainless steel cabinet and inflatable door gaskets isolate cleaning process vapors and condensate, protecting operators and the production area.

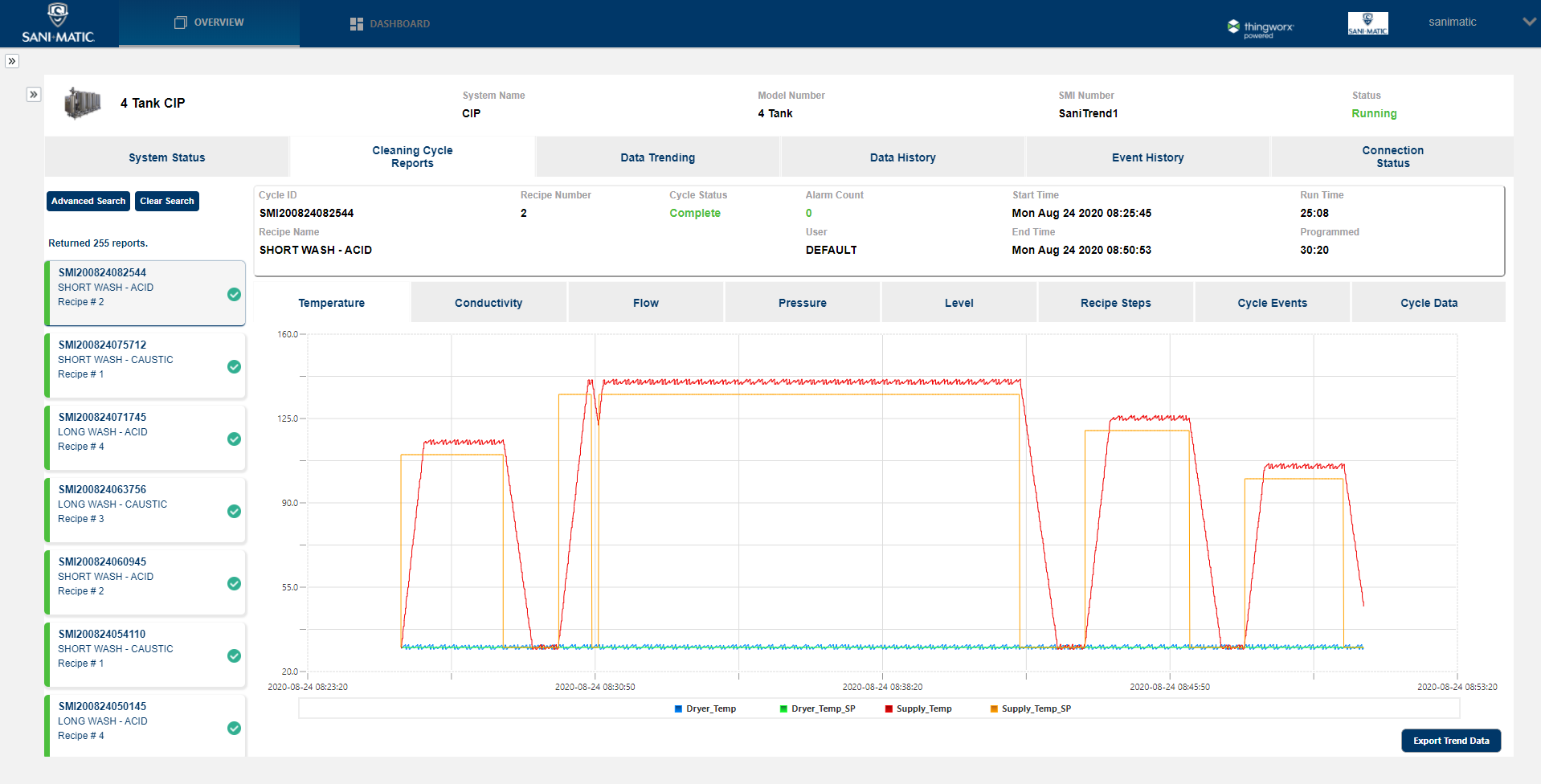

SaniTrend® Cloud or SaniTrend Local software packages are available as options, which enables fully automated reporting functionality, helping to meet FSMA reporting requirements for recording on cleaning & sanitation processes. SaniTrend Cloud’s online functionality also offers additional system insights including Overall Equipment Effectiveness (OEE) trending, live dashboards, preventive maintenance trackers, event notifications, and more.

Resources

View brochures, manuals, technical datasheets, or watch videos for this product.

Articles

Read articles written by industry leaders to share their expertise and recommendations.

Product Resources

Literature

Videos

Product Details

Standard Features

○ 304ss construction

○ Hinged doors with inflatable door gaskets

○ Pre-piped centrifugal supply pump

○ Oscillating spray bars vertically mounted on both sides

○ PLC controls with control interface

○ Automatic temperature and water level controls with alarm and shutdown

○ Automatic temperature and water level controls with alarm and shutdown

○ Direct steam injection heating system

○ PLC Controls with control interface and indicator lights

○ Custom spray manifold/nozzle configuration

○ Custom guide rail container restraint system

○ Automatic final rinse control

How it Works

4-Zone Product Carrier washer

Product Carrier washer interior showing overhead rail for tree loading and oscillating spray bars

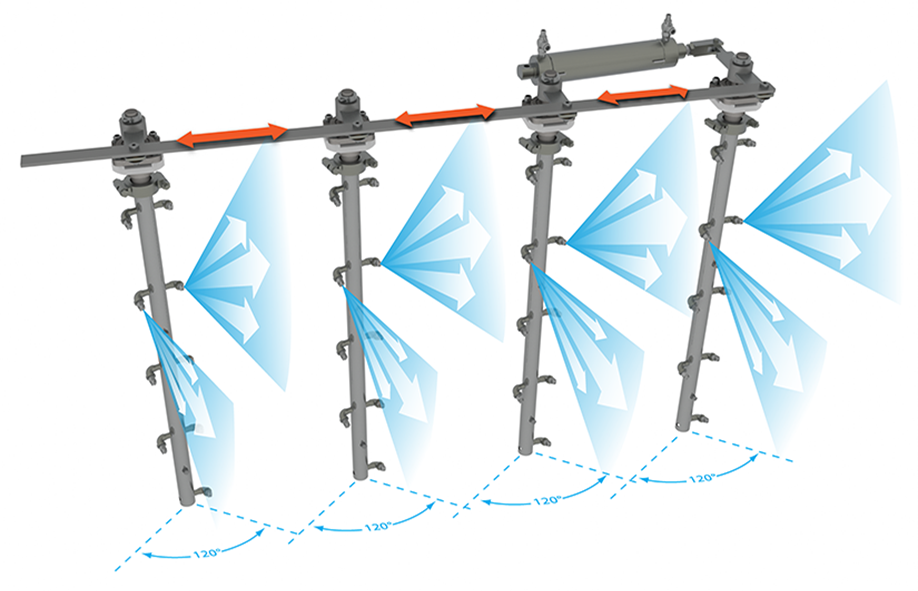

Oscillating sprays in alternating zoned sequence allow higher flow rates, increased dwell times

Spray bars maintain strategically positioned flat-fan sprays and oscillate 120° for full coverage

Custom Options

○ Exhaust fan

○ Conveyorized strainer

○ Steam coil

○ Available in Floor or Pit-Mounted configurations

Automated Electronic CIP/COP

Data Recording, OEE, & More