SaniCab

® PC

Cabinet

Washers

NSF/ANSI/3-A 14159-1 certified washer

built around safe, hygienic design practices

proven to provide complete cleaning.

SaniCab ® PC Cabinet Washers

The Process Equipment, Piston Filler, Bucket, Tray, Pump Components, Hose, and More Washer

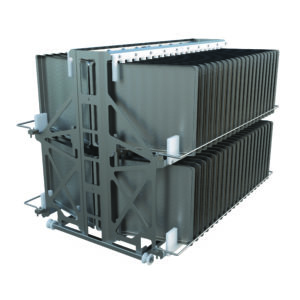

The SaniCab PC is a type of Cabinet or Parts Washer designed to automate your Clean-Out-of-Place (COP) cleaning process. Simply load your dirty parts onto a removable rack, load the rack into the washer, select your cleaning program, and press start. When the wash cycle is complete, remove the rack of clean parts and repeat.

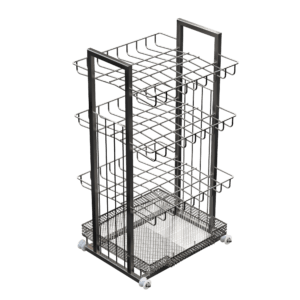

The removable racks can be customized to hold a variety of unique parts, optimizing your productivity, and ensuring you consistently meet your desired cleaning results. These racks are designed for a wide variety of items such as scale buckets, totes, pump components, process fittings, buggies, and much more.

Built around safe, hygienic design practices proven to prevent bacterial contamination

Designed with hygienic standards in mind, select configurations of the SaniCab PC meet industry standards for NSF/ANSI/3-A 14159-1 Hygiene Requirements. While this is ideal for meat, poultry, and dairy applications in Food & Beverage, many applications in the Personal Care & Nutraceutical industry, and even select Bio-Pharm manufacturers can benefit from a cabinet washer meeting this level of hygienic compliance.

Configured to Meet Your Facilities Needs

The SaniCab PC can be configured to meet your specific application and process needs in one of two ways. With our “Configured Design Offerings”, or CDO, you can choose from the standard options available in the model key, located in the Technical Datasheet.

If your needs require specialization outside of the standard options, a custom-engineered solution known as an “Alternative Design Request”, or ADR can be created. An ADR allows for the washer to be customized based on construction, orientation, desired options, or other technical requirements specific to your facility. Either way, we can provide the right solution for you.

Resources

View brochures, manuals, technical datasheets, or watch videos for this product.

Articles

Read articles written by industry leaders to share their expertise and recommendations.

Product Resources

Literature

Videos

Product Details

Standard Features

○ 316L stainless steel construction

○ Sanitary open frame design

○ Floor mounted on adjustable feet

○ Fully welded & color cleaned

○ 32 µin Ra Surface Finish or better with wetted welds ground & polished

○ Welds per AWS D18.1 / D18.1M

○ NSF/ANSI/3-A 14159-1 certified, depending on options selected

○ Two (2) chamber (usable space) sizes:

● PC335 (30″ W x 35″ D x 65″ H)

● PC365 (30″ W x 73″ D x 65″ H)

○ 316L stainless steel sanitary BPE tube and BPE fittings

○ Tri-clamp fittings with heavy duty clamps & EPDM gaskets

○ Low sump volume

○ PLC controls with control interface

○ Software configured to your process

How It Works

The SaniCab Cabinet Washers are very similar to a typical household dishwasher. At home, dirty dishes are loaded into the dishwasher via a sliding rack that is part of the dishwasher. This sliding rack is designed to be generic and hold a wide variety of items.

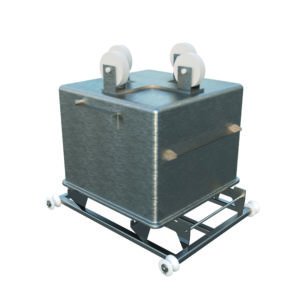

Unlike a dishwasher, the SaniCab uses Racks that can be rolled into or out of the Cabinet Washer using a Transfer Cart. With a Rack loaded, an operator can select from a list of custom clean programs, press start, then resume other tasks.

A typical cleaning program will consist of a Pre-Rinse step to remove any large soils, a Chemical Wash step to remove the remainder of soils, and a Final Rinse step to remove any chemical residue. Depending on your application your cleaning program can last anywhere between 10 minutes to as long as 3 hours.

The SaniCab PC is an improved design of the SaniCab P Cabinet Washer that incorporates the sanitary design practices required to meet the NSF/ANSI/3-A 14159-1 requirements. Functionally, both washers operate identically. To learn more about how the SaniCab Cabinet Washers work, visit the SaniCab P webpage to learn more!

What Differentiates the SaniCab PC

Chamber Construction

When comparing the chambers, the SaniCab PC will have a significantly “simpler & cleaner” look. The SaniCab P has most of it’s piping done inside the chamber, which is supported by several threaded pipe hangers. Additionally, the welds are not ground & polished leaving notches and crevices that cannot be effectively cleaned. The SaniCab PC placing the piping on the outside of the chamber, all welds are ground & polished, and all wetted surfaces are made of 316L stainless steel for better chemical compatability.

Internal vs External Piping

Aside from the piping used on the SaniCab PC being moved outside of the chamber, all piping has been sloped towards a common drain. The chamber strainer has been changed from a pull in/out pan to a recessed, fully drainable basket strainer. The process line strainer has also been upgraded from a Y-Strainer to a more versatile, higher capacity Angle-Line Strainer.

SaniCab P

SaniCab PC

Sanitary Designed Sprays Bars

Spray Bars on the SaniCab P can only be disassembled to a certain level and uses threaded nozzles which cannot be effectively cleaned. The SaniCab PC replaces these nozzles with drilled holes. These drilled holes are also added to the rotating center hub and a spray ball is added to one end of the spray bar to create a unique spray pattern. The entire spray bar assembly is self-cleaning and able to be easily removed and disassembled for easy inspection.

SaniCab P

SaniCab PC

Sealed and Insulated Door

The door on the SaniCab P does not have a gasketed seal to isolate the wash chamber from the outside environment. Rubber skirting and a diverter plate prevent any water from leaking onto the floor.

The SaniCab PC door has an inflatible door seal that, when pressurized, creates a boundary seal between the wash chamber and the outside environment. In addition, the door is insulated to reduce temperature losses

during operation.

SaniCab P

SaniCab PC

Industry Leading NSF/ANSI/3-A 14159-1 Certification

The Sani-Cab PC can be configured to meet and receive certification under the NSF/ANSI/3-A 14159-1 standard. In addition to any structural requirements being met, all plastics and elastomers must meet their specific FDA 21 CFR 177 requirement and all components such as valves and sensors must carry a valid 3-A certificate.

SaniCab PC

Custom Options

○ Custom Chamber Sizes

○ Alternative Material Types or Finishes

○ Changes to Programmable Logic Controller (PLC) and HMI

○ Unique Instrumentation or Component Requests

Featured Options & Accessories

Active Rack Distribution Zone

If you have parts with complex geometry or difficult to clean places, strategically placed spray balls and rotary sprays can be incorporated onto the Rack. During the cleaning process, an additional valve will open supplying water to a coupler inside the washer, activating these strategically placed spray devices to create a unique cleaning option. This allows for unique parts such as jugs, carboys, and even hoses to be effectively cleaned inside and out.

NOTE: The Active Rack currently does not meet NSF/ANSI/3-A 14159-1 standards. If you are interested in including this option and need to certification, please contact us today.

Automated Electronic CIP/COP

Data Recording, OEE, & More