SaniTrend ® Local

Data Acquisition & Management System

Helps to meet FSMA and HACCP regulations for cleaning through recording cleaning cycle wash documentation.

What is SaniTrend Local?

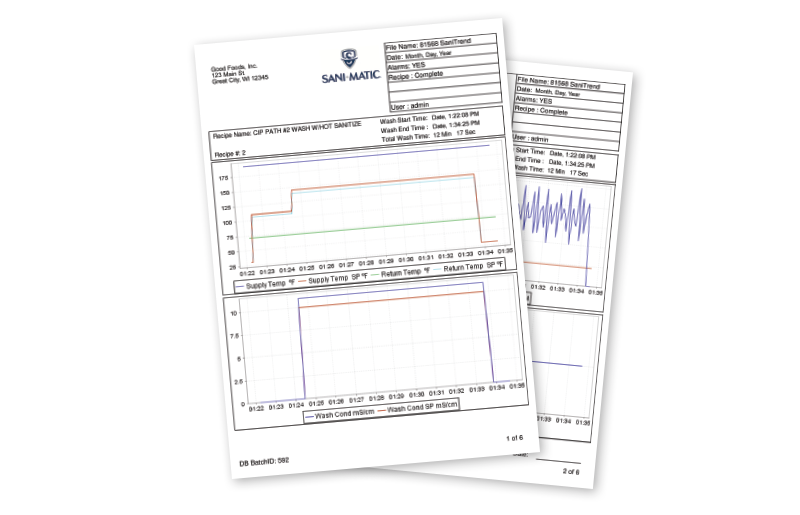

The PC-based SaniTrend Local reporting system is installed on a desktop PC and interfaces with the Sani-Matic cleaning system’s Programmable Logic Controller (PLC) to collect and store cleaning wash cycle data, also known as recipes. An authorized user logs in to the SaniTrend Local PC to select recipes by date or time through a recipe selection screen.

When the recipe is selected the user can view the cleaning wash cycle data as Recipe Chart Data, Recipe Charts and Recipe Events screens.

Operating Requirements

Minimum Programmable Logic Controller (PLC) Requirements: Allen-Bradley® CompactLogix™ Controller or ControlLogix® Controller with Ethernet.

Advantages

Take advantage of a better and easier system than paper chart recorders or manual paper records.

Automated Reporting

Don’t worry about manually collecting data, as all data is automatically recorded right after a cleaning cycle.

Easy-To-Understand Data

Data is available in a clear and concise format for easy analysis.

Diagnostic Analysis

Tracks cycle alarm data, serving as a basic diagnostic tool.

Documented Cleaning

Cleaning wash cycle data is easy to retrieve from storage, helping meet regulatory FSMA and HAACP documentation requirements.

Cleaning System Data Collected

○ Plant name / location

○ Batch ID number

○ Recipe name

○ Analog values and setpoints (flow rates, temperatures, conductivities, pressures monitored depending on available instrumentation)

○ Opcode / step names

○ Alarms

○ Operator Interactions (e.g., Start, Stop, Hold, Abort and Step buttons pressed)

○ Step time

SaniTrend Local Brocure

Click below to open the SaniTrend Local Brochure in a new tab to review or download directly.