Buggy Washer

Buggy Washer

Designed with you in mind, the BWX-600-S Buggy Washer by CleanWorx is an all-electric automated washer specifically designed for cleaning stainless steel dump buggies typically used in the meat, poultry, produce, and baking industries.

Depending on the level of soiling, different wash cycle durations can be selected via an intuitive push-button controller, providing consistent and reliable cleaning of up to 20 buggies per hour.

Buggy Washer

Designed with you in mind, the BWX-600-S Buggy Washer by CleanWorx is an all-electric automated washer specifically designed for cleaning stainless steel dump buggies typically used in the meat, poultry, produce, and baking industries.

Depending on the level of soiling, different wash cycle durations can be selected via an intuitive push-button controller, providing consistent and reliable cleaning of up to 20 buggies per hour.

Product Resources

Literature

Videos

BWX-600-S Operation

See the features and operation of the BWX-600-S Washer.

BWX-600-S Buggy Washer

Typical Packages

BWX-600-S

Buggy Washer

-

Base Package Pricing Includes:

-

(1) BWX-600-S Buggy Washer

-

Contact Us for Lease Application Information

(Monthly Payment Will Vary) -

See Technical Datasheet for Product Details

BWX-600-S

Buggy Washer

+ Preferred Accessories

-

Advanced Package Pricing Includes:

-

(1) BWX-600-S Buggy Washer

-

(1) Digital Process Recorder (DPR) with 1-Year Subscription to DPR Charts Data Reporting (Powered by SaniTrend® Cloud)

-

Contact Us for Lease Application Information (Monthly Payment Will Vary)

-

See Technical Datasheet for Product Details

Accessories

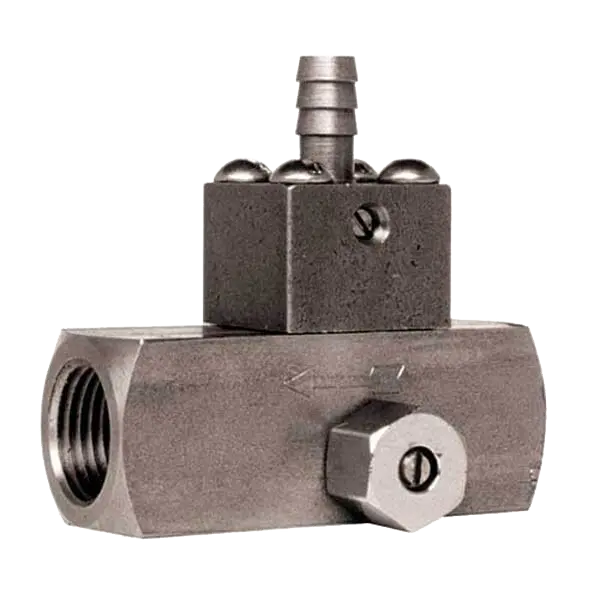

Sanitizer Injection Doser

PART #355019

features

-

Adjustable venturi style valve capable of injecting sanitizer up to 16 oz/min

notes

-

Attaches to final rinse water connection point

-

Chemical and chemical supply tube not included

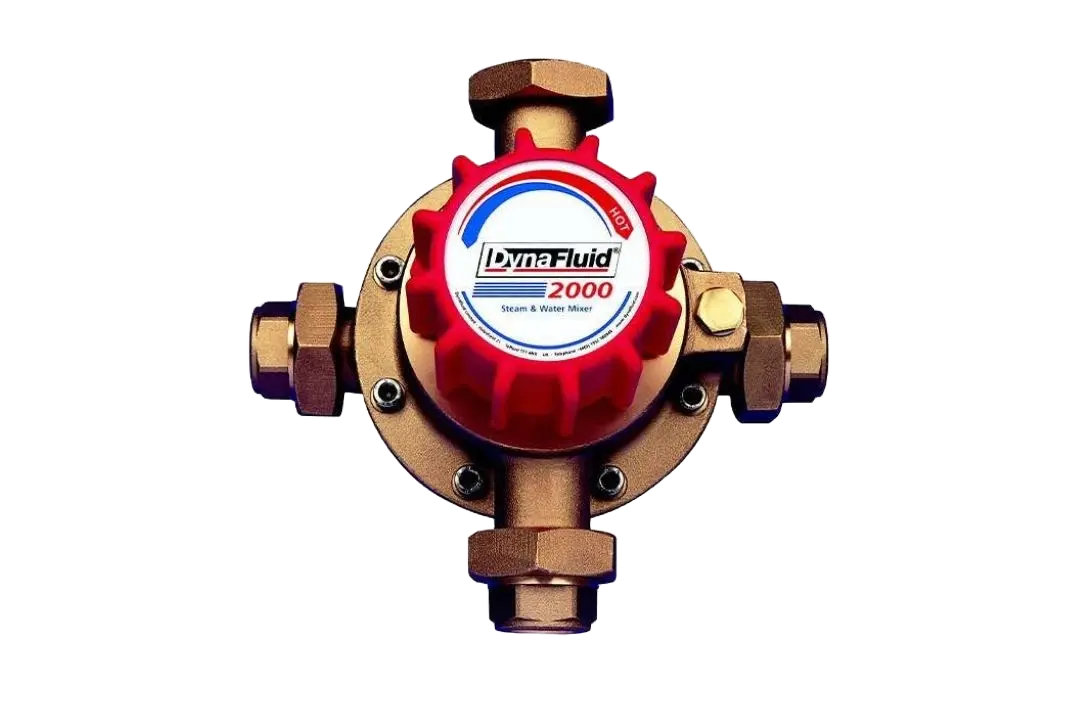

Supply Water Steam Mixing Valve

PART #343316

features

-

Water-Steam Hot Water Mixing Valve

notes

-

Intended for facilities that cannot supply hot water but have steam available

-

Required Water Pressure: 15 – 145 psig

-

Required Steam Pressure: 5 – 145 psig

Digitial Process Recorder (DPR)

With Sensor Kit

PART #354478

+ $1,250 Billed Annually

features

-

DPR Control Panel and 1 Year of DPR Charts Software and Online Access to SaniTrend Cloud Portal

-

Conductivity and Temperature probe installation kit

-

Computer is NOT Included

notes

-

Online data software that provides automated, secure data acquisition of critical cleaning cycle information

-

Users, having a facility user login account, access SaniTrend® Cloud via a web browser

-

Discover more information on the DPR at our website

Start-Up & Training

(Budgetary)

PART #FIELD START-UP AND TRAINING

features

-

Includes Travel Costs, (2) Days of Travel, and (2) Days (16 Hrs Total) of Onsite Support

notes

-

Onsite Technician to help start-up the equipment and train operators.

-

Listed price is budgetary and billed based on actual Time & Material costs.

Preventive Maintenance (PM) Program

(Budgetary; Excludes Material Costs)

PART #FIELD PM PROGRAM

Included features

-

Includes Travel Costs, (2) Days of Travel, and (2) Days (16 Hrs Total) of Onsite Support

notes

-

Onsite Technician to provide Preventive Maintenance (PM) of the equipment.

-

A PM service is recommended to be done annually, or more frequently, depending on operation of the equipment.

-

Listed price is budgetary and billed based on actual Time & Material costs.

Technical Datasheet

Frequently Asked Questions

Space Requirements: 260″ L x 136″ W x 105″ H. Adjustable feet can be used to level the machine. It is recommended to install near an available floor drain.

Electrical Requirements: 100 Amp @ 460VAC, 3 phase, 60Hz

Water Requirements: Supply water between 10-40 gpm with a drain capable of 20 gpm or greater. The supply water temperature is recommended to be 10-15°F hotter than the desired operating temperature.

Exhaust Requirements: Supplied by end-user

An option is a feature or component that is added to a product at time of purchase. This may involve removing components such as the heater, using specific brand parts, or accommodating particular manufacturing requests, such as material finishes. Unfortunately, to maintain consistent pricing and lead times, we cannot accommodate any custom options for individually purchased BWX-600-S Buggy Washers.

If you are an OEM or you are looking to purchase multiple BWX-600-S Buggy Washers, unique customizations and options may be available. If this is of interest, please contact us to discuss your needs further.

The Buggy Washer product line does offer several accessories that can be added to a product after purchase. If you have any questions about our available accessories or if you don’t see an accessory that meets your application requirements, please reach out to us so we can discuss your application in more detail.

A typical cleaning shift for the BWX-600-S Buggy Washer begins with the operator filling the 120-gallon sump with water. The water is then dosed with cleaning chemicals and reused multiple times throughout the shift. This initial 120-gallon fill can last an entire 8-hour shift; however, depending on the type and amount of soil, it may need to be drained, refilled, and re-dosed with chemicals at a different interval. In addition to this fixed sump volume, each buggy being cleaned will use anywhere between 5 to 15 gallons of fresh rinse water to remove any residual chemicals.

The BWX-600-S Buggy Washer is capable of cleaning up to 20 buggies per hour. In cases where the buggies are heavily soiled and require the maximum rinse water (15 gallons per cycle), the total water usage during an 8-hour shift can reach 2,500 gallons. For a different scenario—washing 12 buggies per hour with 10 gallons of rinse water per cycle—water usage can be as low as 1,080 gallons per shift.

How often you inspect and clean your strainer depends on your specific application. We recommend inspecting your strainer frequently until you can establish a maintenance schedule that meets your needs.

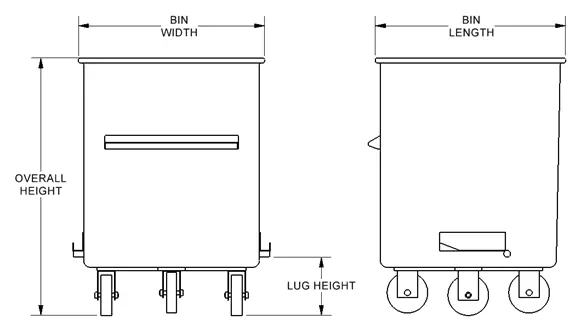

The BWX-600-S Buggy Washer is designed specifically to hold and clean industry-standard 400lbs (300L) and 600lbs (400L) dump buggies, but on-board adjustments can be made to accommodate buggies with the dimensions shown below.

Overall Height = 38″ (max)

Bin Width = 26″ (max)

Bin Length = 27″ (max)

Lug Height = 9-1/8″ (min) / 10-5/8″ (max)

If you would like to discuss your specific buggy dimensions to ensure a proper fit, please contact us today!

The BWX-600-S Buggy Washer has an on-board chemical dispenser that can add chemical to your sump. From a simple on-board controller, you can choose to dose through either timed injection or based on the desired conductivity measured in the sump.

Are you interested in this Buggy Washer, but don’t have CAPEX funding? Sani-Matic’s Leasing Program may be a solution for you.

Benefits Include:

-

Use OPEX Funds for Equipment

-

No Money Down

-

Low Monthly Payments

-

Defer Payment for up to 90 Days

-

3, 4, or 5 Year Terms