Directionally

Drilled

Spray Ball

Assemblies

Have complete confidence in your CIP

process with directionally drilled sprays

Directionally Drilled Spray Ball Assemblies

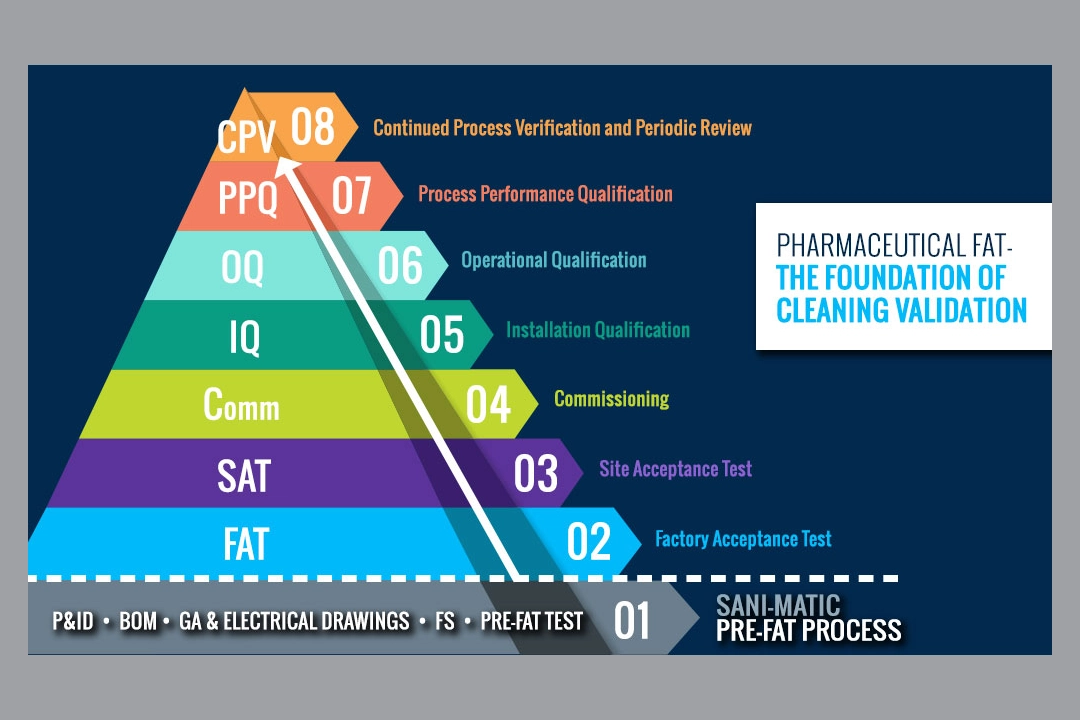

As Clean-In-Place (CIP) system experts for pharmaceutical industries, Sani-Matic has extensive experience designing spray solutions with proper flows, pressures and exact spray patterns to ensure validatable cleaning for your process vessels.

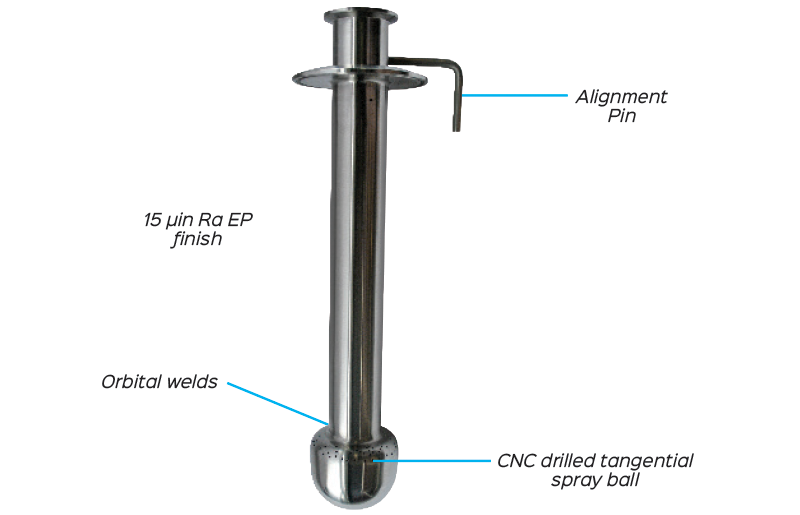

Sani-Matic’s directionally drilled spray ball assemblies meet the latest ASME BPE standards including designs for complete spray coverage, full drainability, proper finish, borescope-inspected orbital welds, and alignment pins for exact, repeatable installation.

Designing for Your Process with Custom-Engineered Solutions

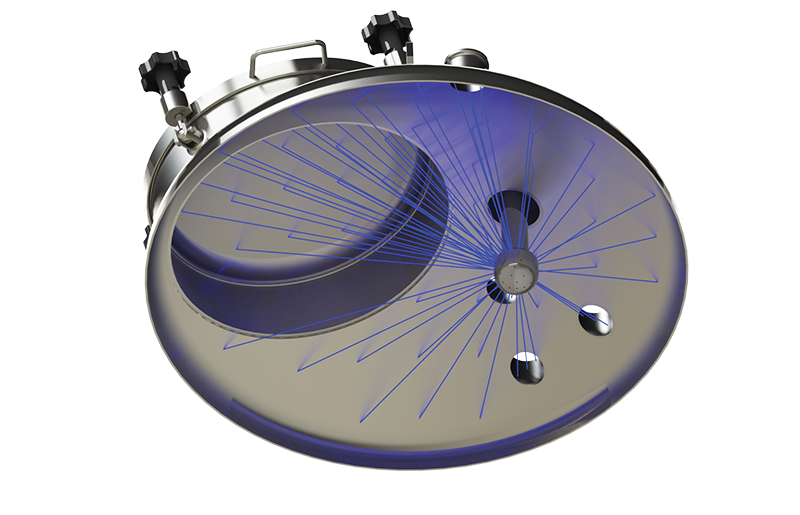

Sani-Matic creates 3-D models of your process vessels to engineer static spray devices with exact drill patterns for full spray coverage of all ports and surfaces to meet validation requirements.

ASME BPE design and testing standards for spray devices such as flow rate recommendations and riboflavin testing procedures are followed and Sani-Matic designers work to understand and identify all potential component process contact surfaces to ensure surface finish specifications are accurate.

Resources

View brochures, manuals, technical datasheets, or watch videos for this product.

Articles

Read articles written by industry leaders to share their expertise and recommendations.

Product Resources

Literature

Videos

Product Details

Standard Features

○ 316Lss

○ Process contact finish: 15 μin Ra

○ Non-process contact finish: 32 μin Ra

○ Alignment positioning pin

○ Orbital Welds

○ CNC drilled spray holes

○ Passivation and Electropolish (optional)

Exact drill patterns ensure full spray coverage

Directionally Drilled Spray Ball Assembly

Documentation (CDP-Premium Package)

Other Packages Available

○ Material Test Reports (MTRs)

○ 3-A Certificate

○ Sani-Matic Certificate of Conformance (CoC)

○ Certified “As-Built” Drawings

○ Heat Map

○ Weld Map

○ Weld Log

○ Surface Finish Certification

○ Electropolish Certification

○ Passivation Certification