Sanitary Dryer L

and L-HP

Standard Dry-In-Place (DIP) skidded system.

Dry sanitary process lines & small equipment.

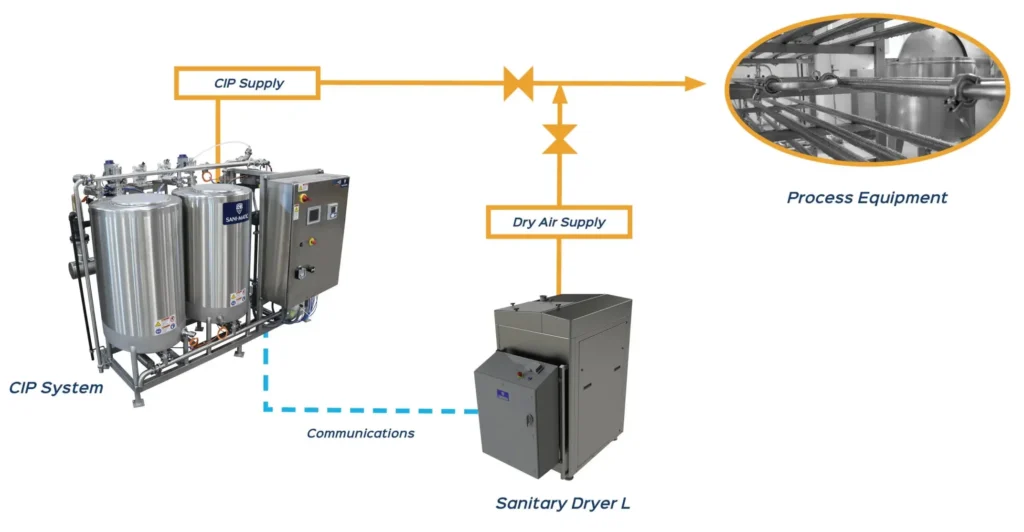

Integrate with automated CIP or use standalone.

Sanitary Dryer L and L-HP

Automate Your Sanitary Drying Processes

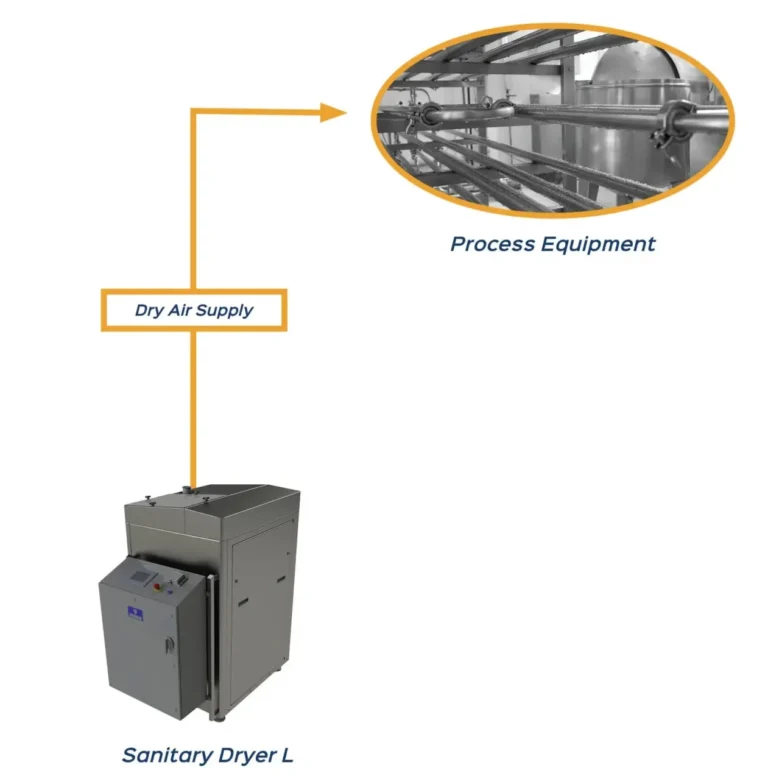

Clean-In-Place (CIP) is a common method to automate the cleaning and sanitization of process lines – but if your process requires drying process lines or small equipment after CIP, it may still be a manual process.

Sani-Matic’s Sanitary Dryer L and L-HP automates this process to make drying as simple as the cleaning process.

Offered in 3 sizes for lines from 1.0″ to 4.0″, the Sanitary Dryer L system takes surrounding air and pre-filters it, delivering it to a regenerative blower controlled via VFD for adjustable setpoints. An electric heater and temperature

sensors help to monitor and control air temperature. Pressure and flow rate sensors allow for monitoring of these variables by the system.

The L-HP model adds HEPA level filtration for high purity applications in industries including personal care, nutraceutical, and bio-pharm, or where a higher filtration level of air drying is required.

SaniTrend ® Cloud or SaniTrend Local software packages are available as options, which enables fully automated reporting functionality, helping to meet FSMA reporting requirements for recording. SaniTrend Cloud’s online functionality also offers additional system insights including Overall Equipment Effectiveness (OEE) trending, live dashboards, preventive maintenance trackers, event notifications, and more.

Resources

View brochures, manuals, technical datasheets, or watch videos for this product.

Articles

Read articles written by industry leaders to share their expertise and recommendations.

Product Details

Sanitary Dryer L Models

L150

L300

L400

Applications (Process Lines – Sanitary Tube Sizes)

1.0″ – 1.5″

2.0″ – 3.0″

3.0″ – 4.0″

Example

Operating

Conditions

60 CFM @

300″ W.C.

200 CFM @

150″ W.C.

350CFM @

80″ W.C.

The HP line of the Sanitary Dryer adds additional filtration through use of a HEPA filter, while maintaining the above specifications.

Controls & Integration Options

CIP System Integration Controls

Stand-Alone Controls