Immersion

Parts Washers

An Efficient, Consistent

Alternative to Manual Cleaning

Immersion Parts Washers

An Efficient, Consistent Alternative to Manual Cleaning

Manufacturing processes have many items that cannot be cleaned-in-place (CIP) such as pipes, hoses, clamps, gaskets, fittings, and other disassembled machine parts.

How does a manufacturer clean these disassembled process parts? Manual labor or a clean-out-of-place (COP) system such as the Sani-Matic Immersion Parts Washer.

Sani-Matic Immersion Parts Washers are designed to meet your individual process needs by eliminating labor-intensive, unreliable manual cleaning with an efficient cleaning solution that provides consistent and repeatable results.

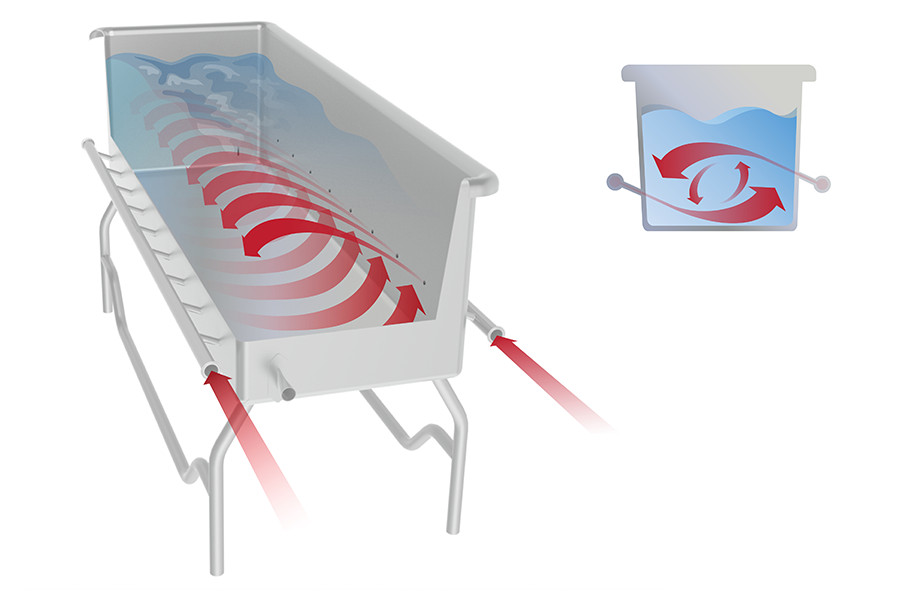

High-velocity turbulence is generated with our exclusively designed jet manifolds to create a consistent, turbulent flow that agitates and removes product residue from process parts. When combined with a wide selection of options, accessories, and control systems ranging from manual to fully automated, the Sani-Matic Immersion Parts Washers can be configured to meet your plant operations and documentation needs.

Each Sani-Matic Immersion Parts Washer is designed to maximize cleaning, while minimizing cycle time and promoting worker safety. That provides you with Cleaning Confidence and a boost to your bottom line.

Cleaning Solution That Can Reach Hard-to-Clean Crevices

Designed specifically for the pharmaceutical and biotechnology industries, Sani-Matic’s Ultrasonic Immersion Parts Washers use transducers to generate high-frequency vibrations to create cavitation bubbles that dislodge soils from hard-to-clean crevices.

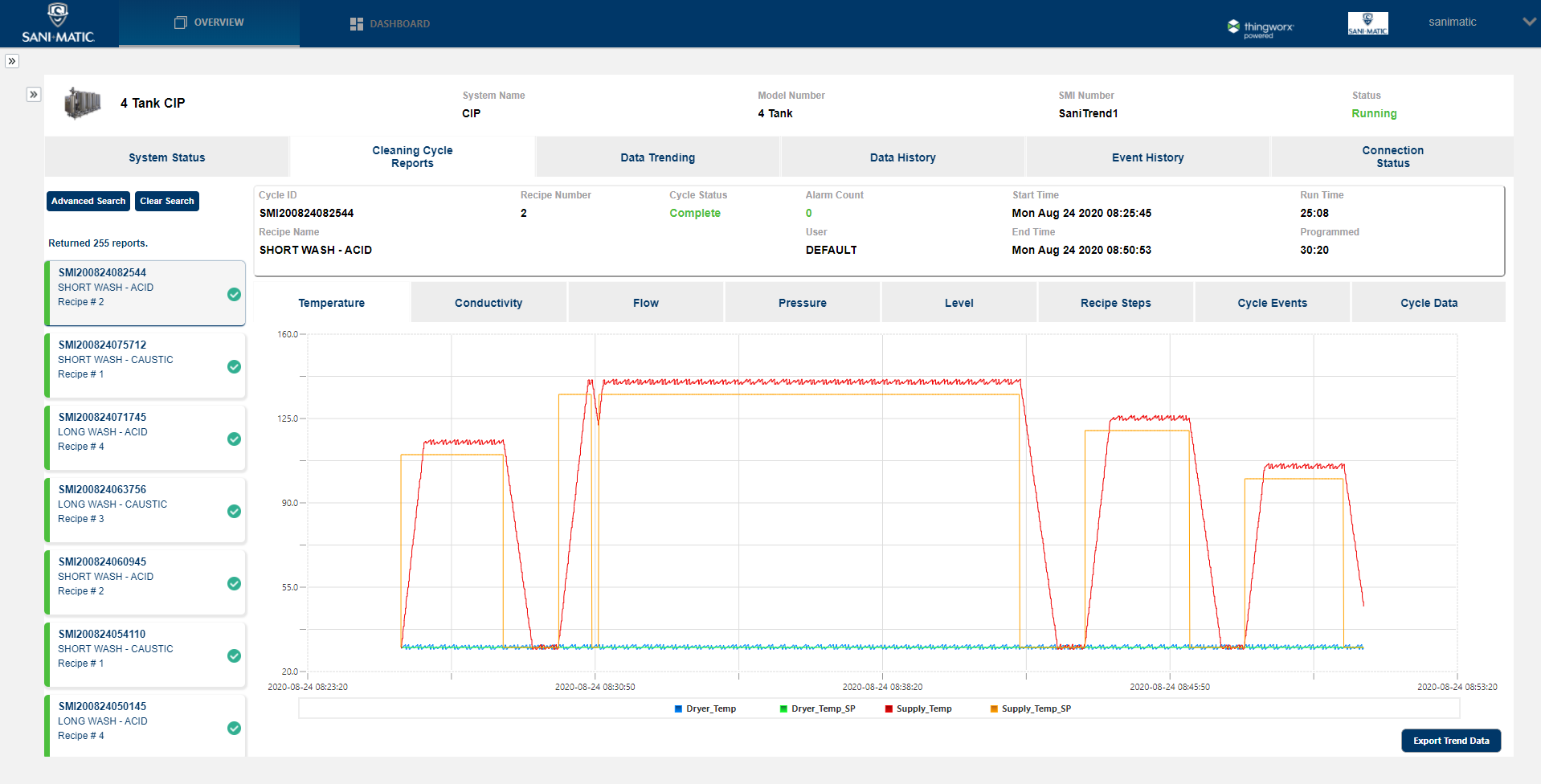

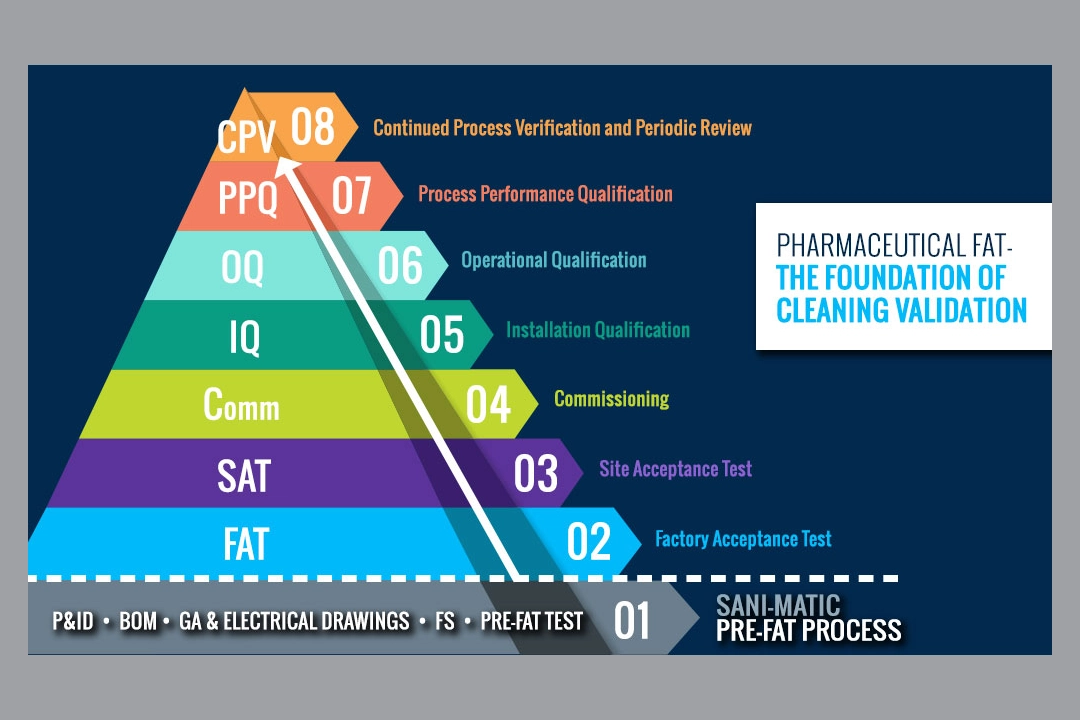

Available with SaniTrend ® Cloud CR Insights+ for Data Acquisition

SaniTrend Cloud provides automated, secure data acquisition and reporting of critical cleaning cycle information. The SaniTrend Cloud CR Insights+ software is available as an option that is fully 21 CFR Part 11 Compliant, helping you meet reporting requirements for recording on cleaning processes. SaniTrend Cloud’s online functionality also offers additional system insights including Overall Equipment Effectiveness (OEE) trending, live dashboards, preventive maintenance trackers, event notifications, and more.

Resources

View brochures, manuals, technical datasheets, or watch videos for this product.

Articles

Read articles written by industry leaders to share their expertise and recommendations.

Product Resources

Literature

Videos

Product Details

Standard Features

○ 316Lss construction

○ 25 µin Ra finish

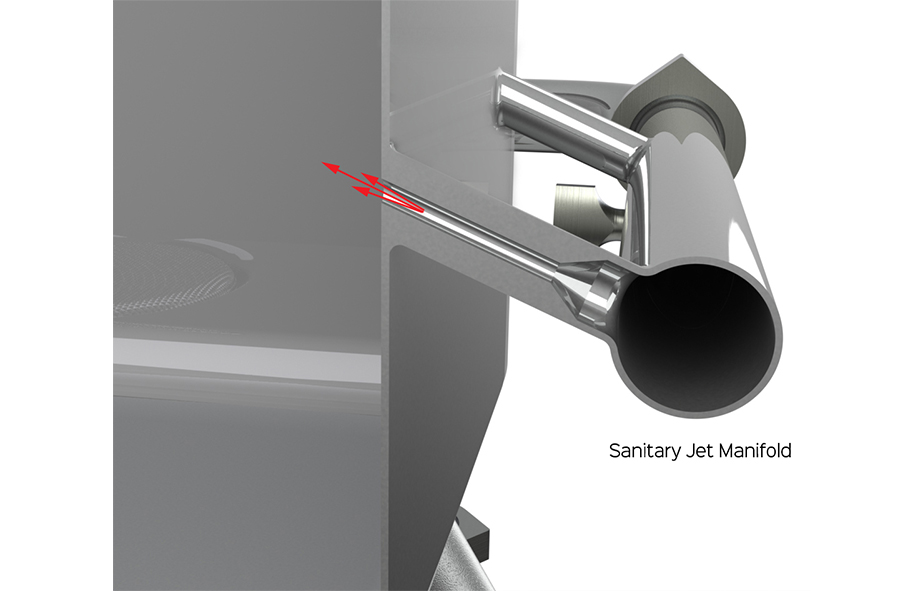

○ Exclusive sanitary jet manifold design

○ Radiused corners

○ Complete documentation to comply with regulatory standards and validation requirements

○ Hinged cover

○ Standard sizes (inner dimensions) include:

· 20″ W x 18″ D (UW Model)

· 24″ W x 22″ D (RW Model)

· 24″ W x 30″ D (PW Model)

· 30″ W x 30″ D (BW Model)

· Custom Dimensions (SP Model)

Note: Standard sizes listed above do not apply to ultrasonic washers

○ 4, 6, 8, 10, or 12 ft lengths available

Sani-Matic’s exclusive sanitary jet design eliminates bacteria-harboring crevices

Side jets create circular, turbulent flow for a complete clean

Custom Options

○ 20 µin Ra, wetted finish

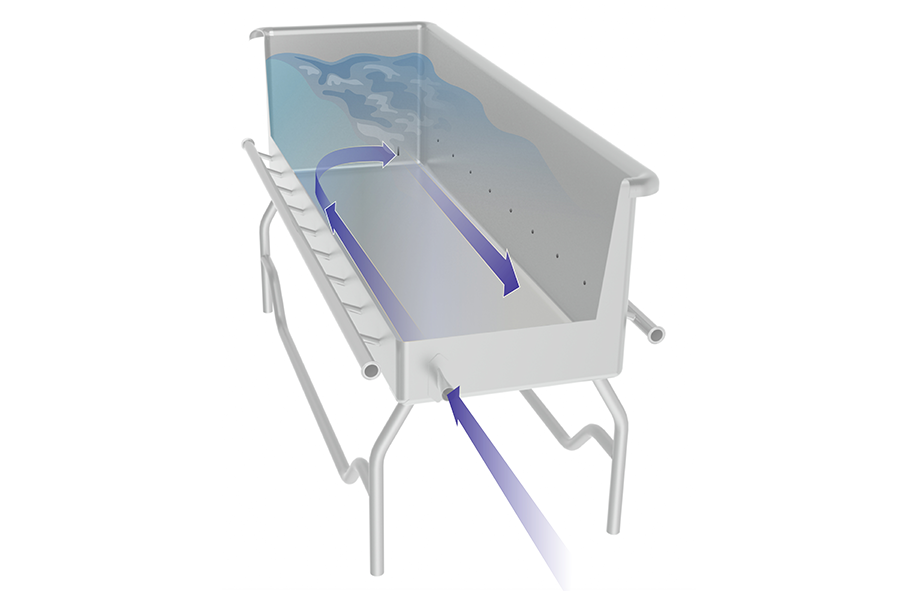

○ End-jet manifold assembly

○ Semi or fully automated controls

○ Conductivity sensor and controller

○ Chemical feed equipment

○ In-line electric heater or shell and tube heat exchanger

○ Inflatable gasket cover

○ Insulated tank side walls

○ Hose cleaning manifold assembly

○ Heavy-duty stainless steel casters

○ Manual diaphragm valve cleaning manifold

○ Custom fixtures and racks

○ Flow meter

○ Custom tank sizes

Optional end jets create longitudinal flow for hose and pipe cleaning

Optional hose cleaning manifolds are available

Automated Electronic CIP/COP

Data Recording, OEE, & More