PharmaCab ® MP

High-Throughput GMP Washer

Cleans Entire Suite in One Cleaning Cycle

PharmaCab ® MP

High-Throughput GMP Washer Cleans Entire Suite in One Cycle

Sani-Matic’s hygienic GMP cabinet washers help bio-pharm industry manufacturers meet strict process cleaning standards to achieve documentable clean, every time.

The Sani-Matic PharmaCab MP Series is an automated cabinet washer engineered to thoroughly clean and dry an entire suite in one load including tableting process items, trays, pans, buckets, totes, filter housings, drums, hoses, fittings, utensils and more.

The PharmaCab MP Series design meets cGMP and complies with the latest ASME BPE Cabinet Washer Standards.

Rotating and oscillating spray bars with targeted spray nozzles ensure an even distribution of solution for complete cleaning coverage of all process parts and the wash chamber’s interior. A 40-recipe PLC controls with easy-to-navigate HMI generate repeatable, documentable results.

The GMP washer delivers repeatable and documentable cleaning and drying results with a series of important features:

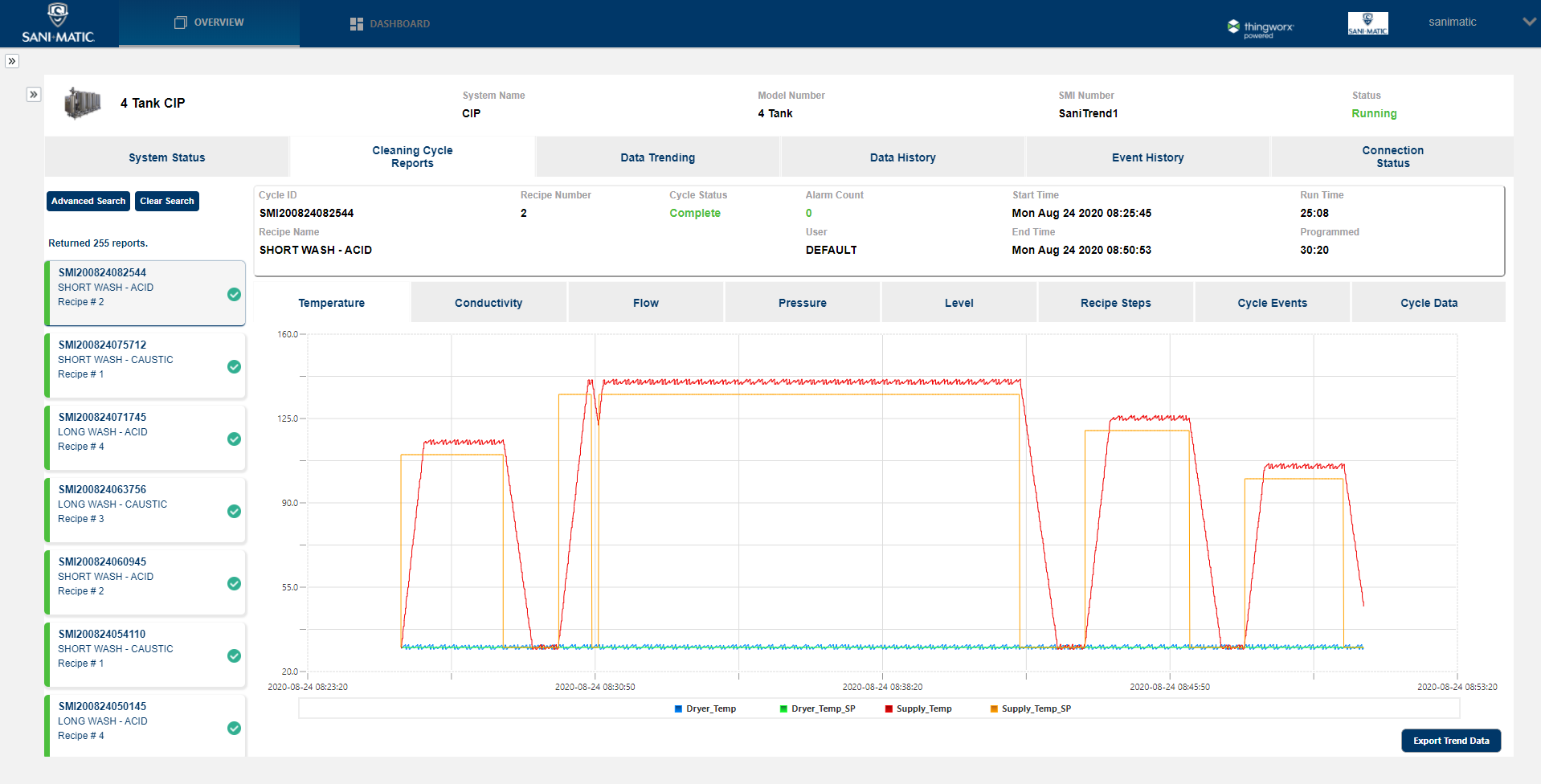

Available with SaniTrend ® Cloud CR Insights+ for Data Acquisition

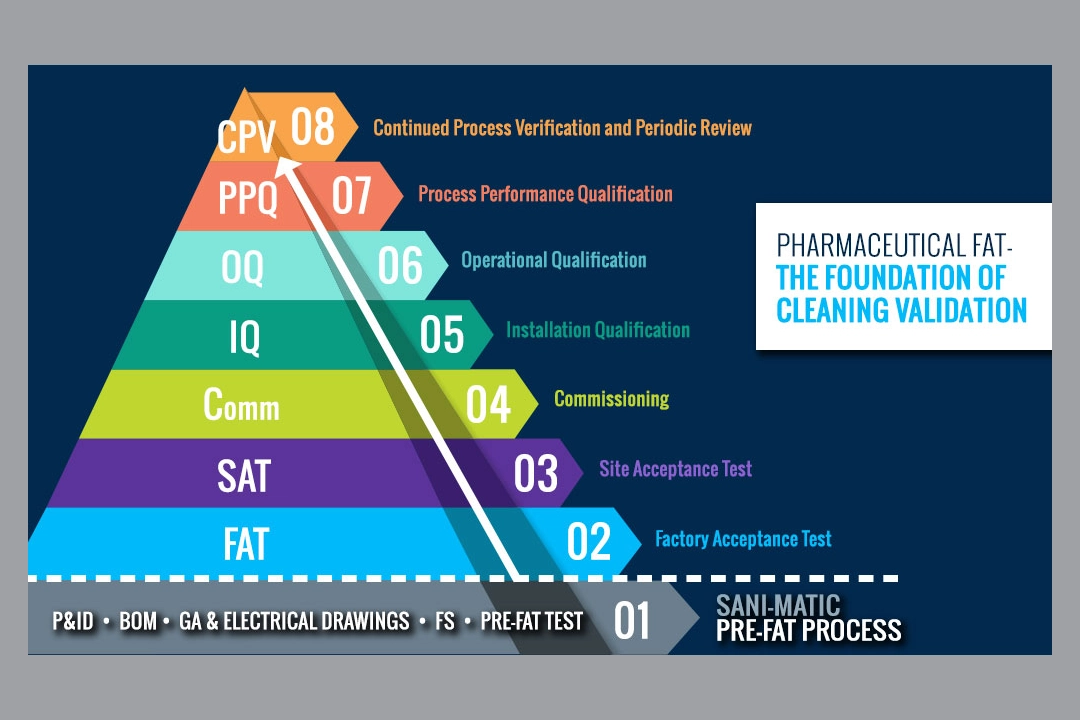

SaniTrend Cloud provides automated, secure data acquisition and reporting of critical cleaning cycle information. The SaniTrend Cloud CR Insights+ tier is available as an option that is fully 21 CFR Part 11 Compliant, helping you meet reporting requirements for recording on cleaning processes. SaniTrend Cloud’s online functionality also offers additional system insights including Overall Equipment Effectiveness (OEE) trending, live dashboards, preventive maintenance trackers, event notifications, and more.

Resources

View brochures, manuals, technical datasheets, or watch videos for this product.

Articles

Read articles written by industry leaders to share their expertise and recommendations.

Product Resources

Literature

Videos

Product Details

Standard Features

○ Wetted 316Lss, 25 µin Ra, Non-wetted 304ss 32 µin Ra

○ Fully radiused chamber corners

○ Single door design

○ Pneumatically inflatable elastomeric door gaskets

○ Allen-Bradley CompactLogix PLC with PanelView HMI

○ Non-threaded, 1/4 turn removable spray nozzles

○ Proof of rotation sensors

○ Custom-designed racks with active sprays

○ External CIP supply and recirculation assembly supplies solution to cabinet

○ External dryer system with HEPA filer

○ Chemical delivery, two pumps provide accurate dosage of chemicals

○ Pit-mounted design

Oscillating spray arms for full spray coverage

Rotating spray arms with proof of rotation sensor

Custom Options

○ Double door (pass-through) design

○ Seismic zone anchorage calculations

○ Barrier flanges

○ Drain cooling valve

○ Remote chemical supply

○ 20 µin Ra finish

○ Passivation

○ Sample station

Automated Electronic CIP/COP

Data Recording, OEE, & More