SaniCab

® PC

Cabinet

Washers

Built around NSF/ASNI/3-A hygiene requirements

proven to provide hygienic automated cleaning.

SaniCab ® PC Cabinet Washers

The Tableting Parts, Pump Components, Filler Parts, Bucket, Tray, Hose, Glassware, and More – Washer

The SaniCab PC is a type of Cabinet or Parts Washer designed to automate your Clean-Out-of-Place (COP) cleaning process. Simply load your dirty parts onto a removable rack, load the rack into the washer, select your cleaning program, and press start. When the wash cycle is complete, remove the rack of clean parts and repeat.

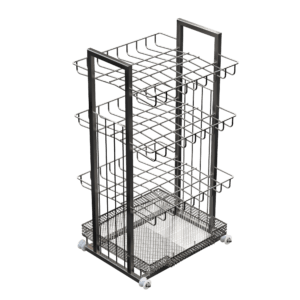

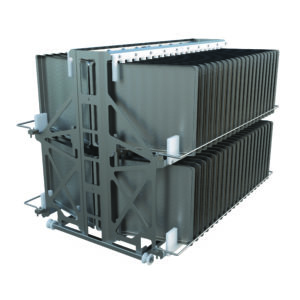

The removable racks can be customized to hold an assortment of unique parts, optimizing your productivity, and ensuring you consistently meet your desired cleaning results. These racks are designed for a wide variety of items such as buckets, glassware, hoses, trays, pump components, tableting parts, fillers, and much more.

A cost-effective solution for non-critical pharmaceutical applications

Designed to high hygienic standards, the SaniCab PC is the ideal solution for bio-pharmaceutical manufacturers looking for a cost-effective washer solution as an alternative to a full cleanroom environment washer like Sani-Matic’s PharmaCab SP product line. Applications for this washer can be non-critical/non-sterile process parts or can clean process parts in an environment that doesn’t need integration of the washer into a clean room type environment. The washer is also ideal for cleaning of single-use components prior to being used in a cleanroom environment.

Configured to Meet Your Facilities Needs

The SaniCab PC can be configured to meet your specific application and process needs in one of two ways. With our “ Configured Design Offerings”, or CDO, you can choose from the standard options available in the model key, located in the Technical Datasheet.

If your needs require specialization outside of the standard options, a custom-engineered solution known as an “ Alternative Design Request”, or ADR, can be created. An ADR allows for the washer to be customized based on construction, orientation, desired options, or other technical requirements specific to your facility. Either way, we can provide the right solution for you.

Resources

View brochures, manuals, technical datasheets, or watch videos for this product.

Articles

Read articles written by industry leaders to share their expertise and recommendations.

Product Resources

Literature

Videos

Product Details

Standard Features

○ 316L stainless steel construction

○ Sanitary open frame design

○ Floor mounted on adjustable feet

○ Fully welded & color cleaned

○ 32 µin Ra Surface Finish or better with wetted welds ground & polished

○ Welds per AWS D18.1 / D18.1M

○ NSF/ANSI/3-A 14159-1 certified, depending on options selected

○ Two (2) chamber (usable space) sizes:

● PC335 (30″ W x 35″ D x 65″ H)

● PC365 (30″ W x 73″ D x 65″ H)

○ 316L stainless steel sanitary BPE tube and BPE fittings

○ Tri-clamp fittings with heavy duty clamps & EPDM gaskets

○ Low sump volume

○ PLC controls with control interface

○ Software configured to your process

How it Works

The SaniCab Cabinet Washer is very similar to a typical household dishwasher. At home, dirty dishes are loaded into the dishwasher via a sliding rack that is part of the machine. This sliding rack is designed to be generic, able to hold a wide variety of items. Once full, detergent is then added, the desired washing cycle selected, and the machine runs as programmed.

Unlike a home dishwasher, the SaniCab uses Racks with 360 degrees of access for loading soiled parts. With multiple Racks, operators can unload clean parts and reload dirty parts onto one Rack while another Rack of parts is being cleaned – streamlining the cleaning process and saving time.

While Generic Racks are available, each process and application normally have diverse parts with varying types of soils that need to be removed. For that reason, Sani-Matic offers Custom-Designed Racks that are engineered to meet the exact geometry of each part for optimum surface exposure and drainage.

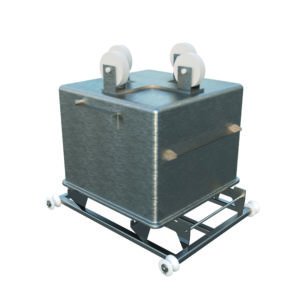

Once the Rack is filled with dirty parts, it is loaded into the SaniCab using a Transfer Cart. The operator opens the Cabinet Washer door, pushes the Transfer Cart to align with the loading rails, and rolls the rack into the washer chamber. They then remove the Transfer Cart automatically locking the rack in place, close the Cabinet Washer door, and the SaniCab is ready to run.

From the nearby touchscreen, the operator selects from a list of available cleaning programs. These cleaning programs are fully automated and require no additional steps once the Start button has been pressed. Depending on the application, cleaning programs can be as short as 10 minutes or as long as 3 hours, allowing time for the operator to perform other tasks.

A typical cleaning program will consist of a Pre-Rinse step, a Chemical Wash step, and a Final Rinse step. The Pre-Rinse step is used to remove any large surface soils. The Chemical Wash step is typically heated and introduces a non-foaming cleaner to remove the remaining soils. The Final Rinse step is intended to wash away any remaining chemical residue. Additional steps can be added if, for example, a Sanitizing step is needed.

Cleaning programs are customized to your exact process requirements and can only be modified, or new programs created, by an operator with appropriate permissions. This ensures your process is repeatable, and your parts are consistently cleaned to your required standards.

The SaniCab uses multiple rotating Spray Bars mounted inside the chamber to spray pressurized water onto the dirty parts. Each spray bar is outfitted with a series of spray nozzles, creating an effective, multi-directional area of coverage to clean each part as it sits on the Rack.

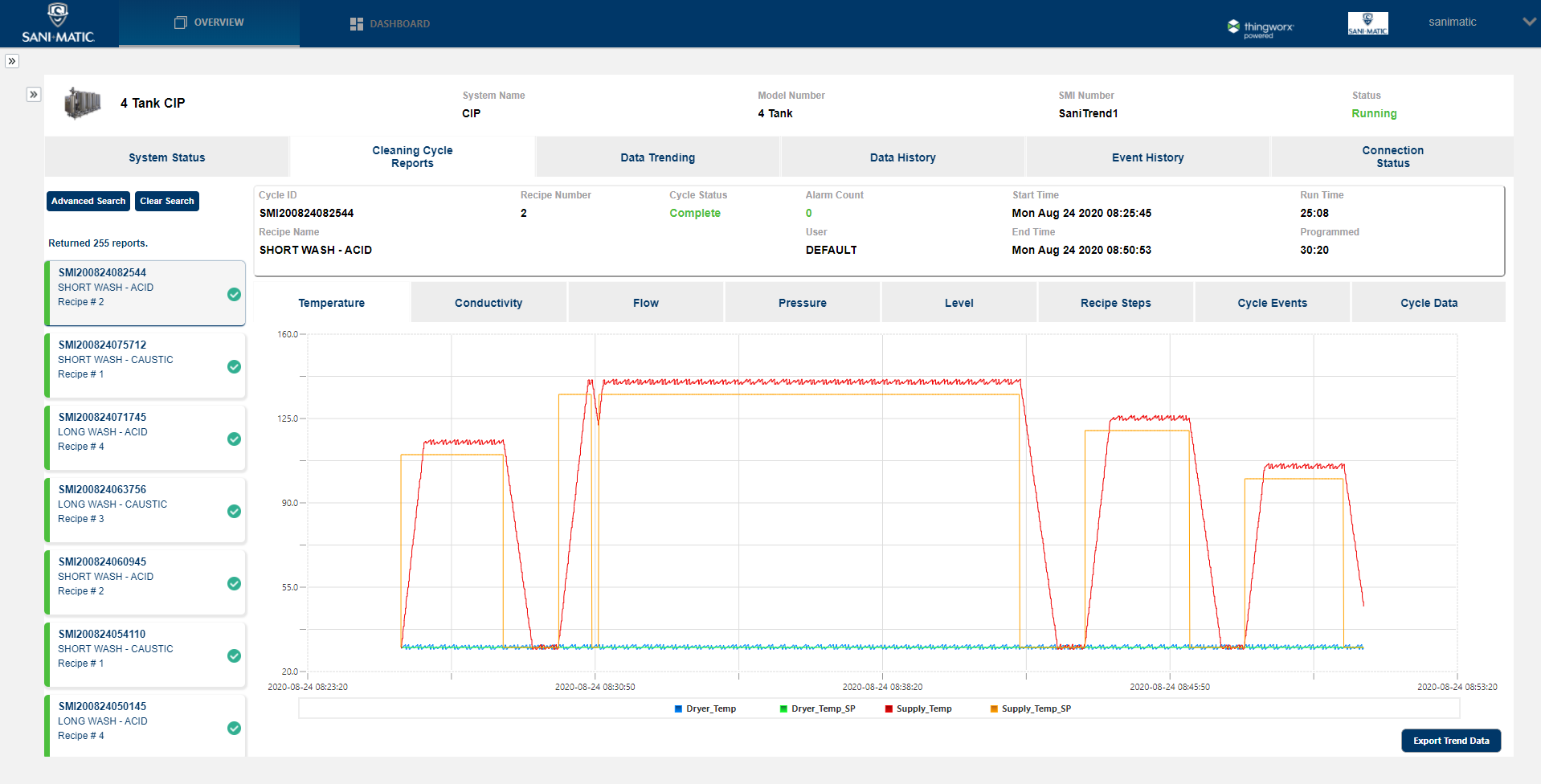

While the cleaning program is running, the SaniCab’s Programmable Logic Controller (PLC) is collecting wash cycle data from each sensor and event. Similar to a physical chart recorder, this data is stored for later use, but it can also connect to digital products like SaniTrend Local or SaniTrend Cloud to give operators the ability to better analyze the data, view trends, receive real-time e-mail/text alerts, and more!

Once the cleaning program is completed, clean parts will typically have residual water on their surfaces. If your process requires your parts to be dry, an optional Dryer can be incorporated to dry your parts after your cleaning cycle is complete. Once the cleaning and optional drying cycles are complete, the Rack can be removed, and the next round of parts washing can begin.

Custom Options

○ Custom Chamber Sizes

○ Alternative Material Types or Finishes

○ Changes to Programmable Logic Controller (PLC) and HMI

○ Unique Instrumentation or Component Requests

Featured Options & Accessories

Active Rack Distribution Zone

If you have parts with complex geometry or difficult to clean places, strategically placed spray balls and rotary sprays can be incorporated onto the Rack. During the cleaning process, an additional valve will open supplying water to a coupler inside the washer, activating these strategically placed spray devices to create a unique cleaning option. This allows for unique parts such as jugs, carboys, and even hoses to be effectively cleaned inside and out.

NOTE: The Active Rack currently does not meet NSF/ANSI/3-A 14159-1 standards. If you are interested in including this option and need to certification, please contact us today.

Automated Electronic CIP/COP

Data Recording, OEE, & More