Digital

Process

Recorder

(DPR)

Easy and Automated Data Collection.

Replace Paper Chart Recorders.

Increase Operational Efficiency.

Digital Process Recorder (DPR)

Everything Needed for Automated Data Collection

The Digital Process Recorder (DPR), Powered by SaniTrend® Cloud, is an automated software solution providing secure acquisition and storage of critical process data. The DPR can replace traditional data collection methods like paper chart recorders.

The DPR provides critical data collection for applications like process equipment data collection, Clean-In-Place (CIP), Clean-Out-of-Place (COP), and more.

Two product tiers of the DPR family are available – Charts and Reports. The Charts tier includes interactive data storage and comment/review functions, along with live dashboard views, email & text notifications, and more.

The Reports tier takes a “running signal” from the process and organizes the data into discrete reports, allowing for easier review of report-based data.

Resources

View brochures, manuals, technical datasheets, or watch videos for this product.

Articles

Read articles written by industry leaders to share their expertise and recommendations.

DPR Product Tiers

Using the same DPR control panel, choose an offering that meets your data collection needs.

Charts

Reports

Product Resources

Literature

Videos

Paper Chart Recorder Comparison

Why moving away from a paper-based solution can improve your process efficiencies.

Digital Process Recorder

VS.

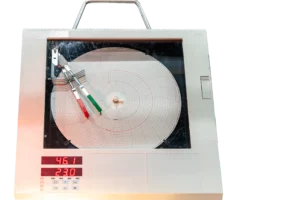

Paper Chart Recorder

Data Review Process

Review data quickly from your phone, tablet, or computer.

Eight (8) Analog Signals

Standard offering includes inputs for up to eight analog input signals.

Data Review Process

Retrieve paper, find and bring the paper to the necessary people, hand-written comments & sign-off.

Four (4) Analog Signals or Less

Typically 1-2 pen options; 3 and 4 pen options available but become expensive

Ease of Data Review

Easy-to-read, scalable, digital trending charts. Export data to excel tables as needed. Interactive to show various data points together.

Ease of Data Review

Confusing circular chart, hard to read & interpret data.

Data Storage

Data is automatically stored and backed up in the cloud for as long as you need it.

Data Storage

Data is manually brought to a local or offsite storage location.

Data Retrieval

Data is easily available and searchable by time and date.

Data Retrieval

Retrieve paper from local or offsite storage, having to search for applicable records required.

Additional Features

Cloud documentation storage, email & text notifications. Up to (12) Digital Input signals (e.g., pump running, valve status) for additional insights.

Additional Features

None.

Maintenance

Generally maintenance free.

Maintenance

Replace paper charts, replace pens, replacement of mechanical items as needed.

Replacing Chart Recorders with Automated Solutions

While software for automated data collection exists, sometimes making the transition from the manual to automated methods can be tough.

Read more in our article about how the Digital Process Recorder (DPR) can make the transition away from paper chart recorders easier.

Access the SaniTrend® Cloud

Online Portal