Selecting the most appropriate sanitary process components for straining a specific application can mean the difference between a big headache and big success, according to Jack Herbert, customer service manager at Sani-Matic. That’s why Sani-Matic plays a large role in helping its customers choose the right strainer for the job.

“There is such a difference in strainer needs from application to application,” Herbert said. “Look at the explosion in craft breweries. The strainers in this industry are so diverse because of the unique needs dictated by the variety of flavors being created. Their strainers often require special wedgewire sizes to strain hops, pumpkin and citrus pulp—or to be used as a hopback.”

“Other beverages also bring unique challenges,” said Wayne Huebner, applications engineer at Sani-Matic. “Tomato- and citrus-based products are highly acidic and often require different materials such as AL-6XN alloy. It is also important to choose the best strainer insert for these beverages because they determine how much pulp or percentage of solids make it into the product, and they prevent premature plugging. With milks and yogurts, you need to be careful because the properties of those products can be affected depending on how fast they are flowing through the process line. And, in chocolate, you don’t want congealing, so a hot water jacket is often required.”

Customer knowledge on strainer types and how they apply to individual applications can vary.

“Even if the customer is looking for standard sanitary process components, the first question we ask is, ‘what is the application?’,” Herbert said. “This is where our customer service people ask penetrating questions to ensure the customer gets what they need for their process.”

Sani-Matic’s depth of expertise and knowledge spans across many food, beverage and bio-pharmaceutical markets.

“When we’re working with a pharmaceutical manufacturer, products are pretty predictable in terms of which wedgewire we use. The difference for this industry is the strict standards in place for the materials used, welding techniques and material finish—more than likely it’ll require electropolishing,” said Brian Schaal, mechanical designer at Sani-Matic. “These standards help minimize risk of product contamination and are an integral part of working with our pharmaceutical customers,” Schaal added.

Food and beverage manufacturers may require sanitary process components that are certified 3-A. “Our In-Line, Basket and Y-Strainers involving perforated inserts are 3-A certified, and, even though wedgewire inserts are not, 3-A standards do allow the use of wedgewire material. We keep that in mind for our customers and help clarify it for them,” said Huebner.

Our decades of experience have helped us hone the information gathering process at the front-end to develop custom solutions that other companies won’t even attempt to quote.

Sanitary Process Components – Beyond choosing the strainer

“Beyond helping our customers choose the right strainer, we help guide them on issues such as how often they need to change the filter media or how to know when the strainer is plugged,” said Huebner.

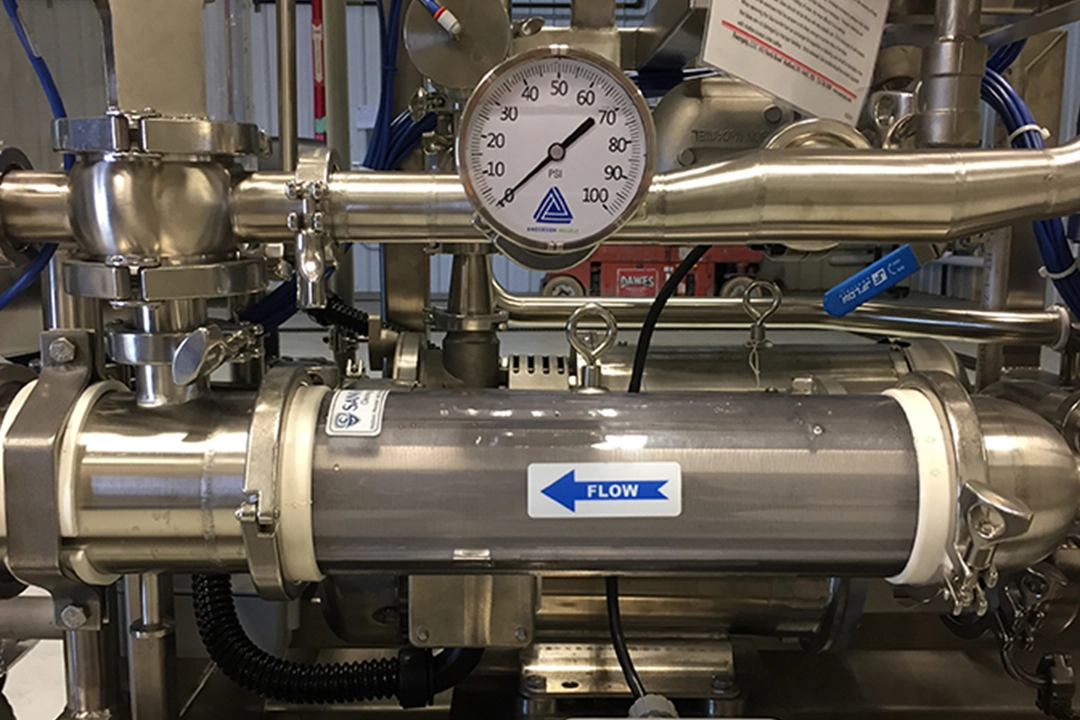

“When our customers ask us how to tell if the strainer needs to be cleaned, we suggest placing a pressure gauge before and after the strainer so they can watch for a pressure drop. If the gauge after the strainer shows a pressure drop of 8 to 10 psi, then it is time to clean the strainer. It is an inexpensive solution that really helps our customers’ productivity. They rely on us to provide these types of answers for them,” added Huebner.