Strainers

Protecting Your Equipment, Your Product

Integrity, and Your Bottom Line

Strainers

Protecting Your Equipment, Your Product Integrity, and Your Bottom Line

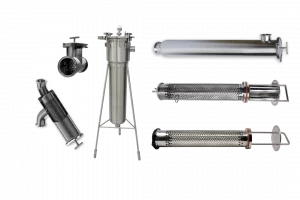

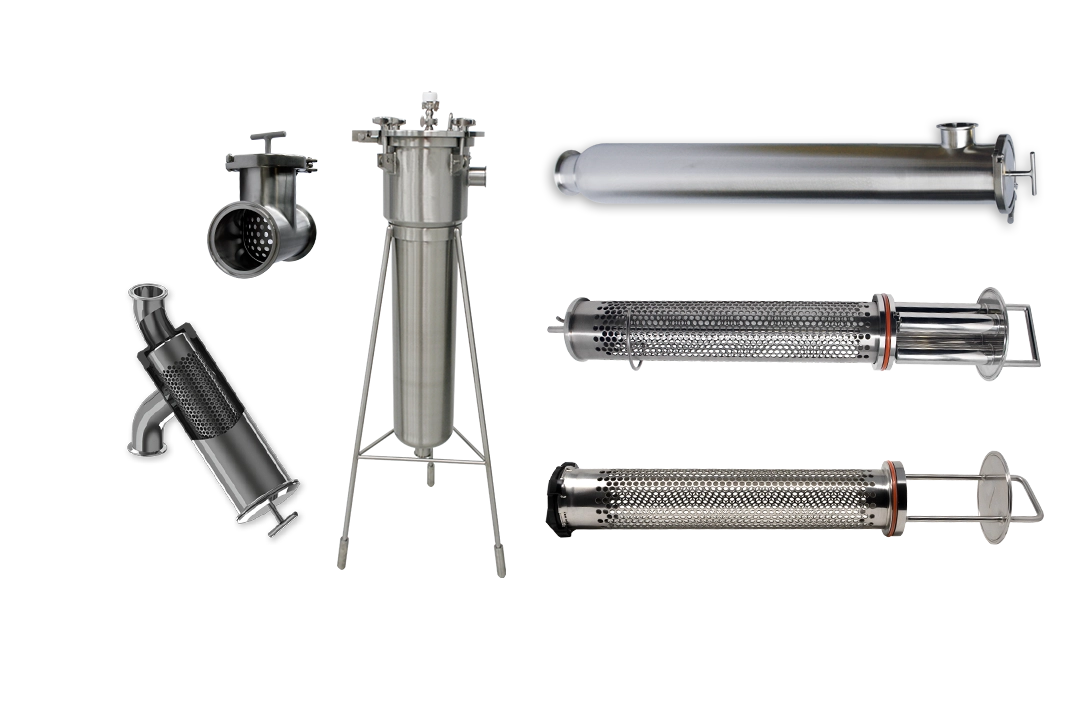

Strainers are a critical part of your process. They help maximize production efficiencies, protect your valuable equipment, and ensure product integrity.

That is why we manufacture a large variety of strainers that are sanitary in design, constructed from durable stainless steel, and easy to disassemble and clean.

We proudly manufacture and distribute all our products from our state-of-the-art manufacturing facility in Sun Prairie, WI, USA. We stock a large variety of strainers and strainer components, allowing us to provide you with the solution you need, when you need it.

Select strainers are designed and certified to the 42-02 (Sanitary Standard for In-Line Strainers) 3-A standard. When considering a strainer that requires 3-A certification, contact a Sani-Matic representative.

Resources

View brochures, manuals, technical datasheets, or watch videos for this product line.

Amazon Store

Order some of the most common off-the-shelf sanitary components, accessories, and parts.

Hygienic Component Solutions Catalog

Click below to open the catalog in a new tab to review or download.

Solutions We Provide

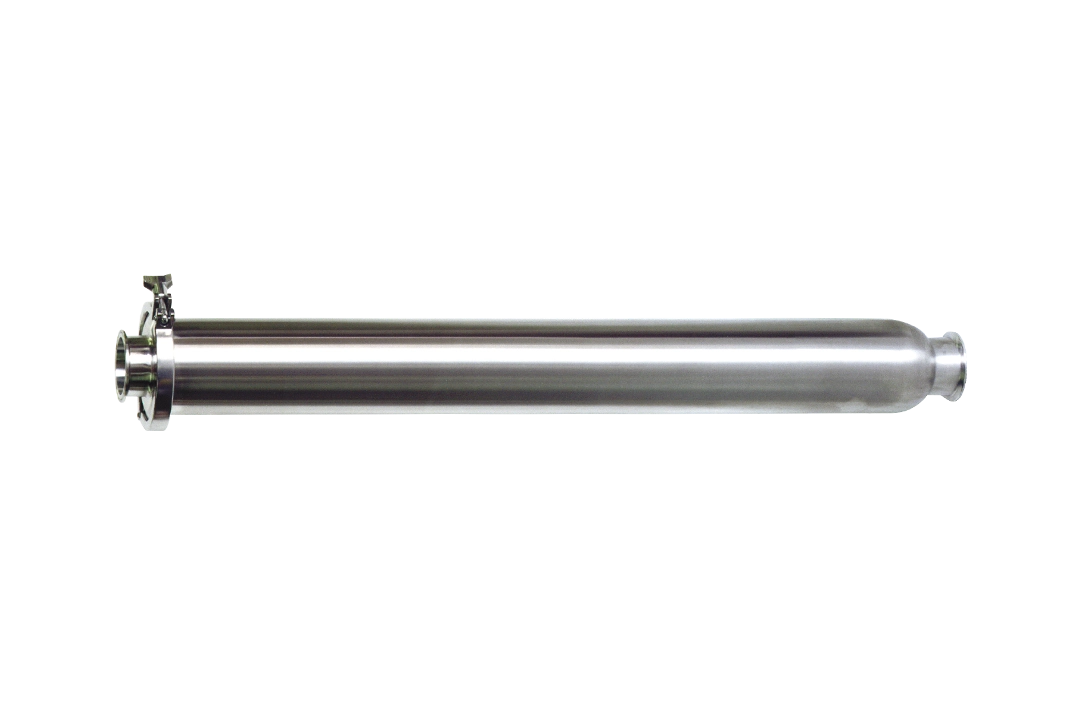

Straight-Line

Strainers

Remove soils and protect equipment.

Must break from process line to clean.

3-A authorized when using perf elements.

Angle-Line

Strainers

Choose from side or end flow configurations.

Clean without removing from the process line.

Multiple sizes and options available.

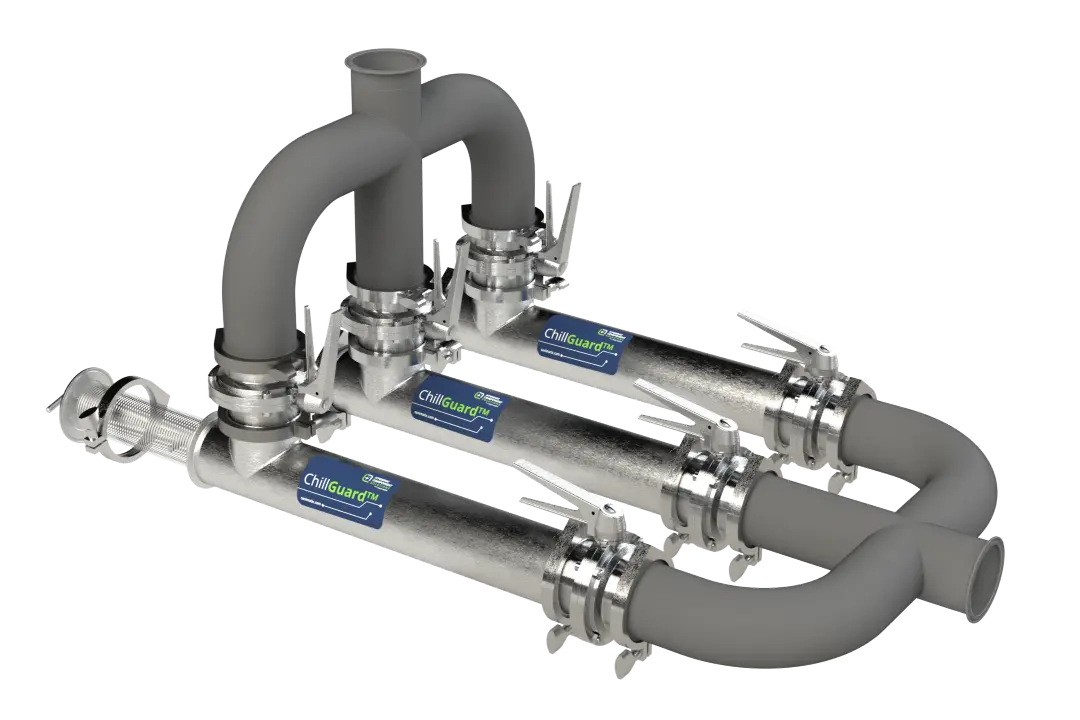

ChillGuard™

Strainers

The Ultimate Solution for Liquid Cooling Applications.

Angle-Line Basket (ALB) Strainer

Capture soils in a fully removable basket.

Uses same body as Angle-Line Strainer.

Patent Pending easy flush end cap design.

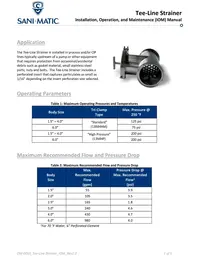

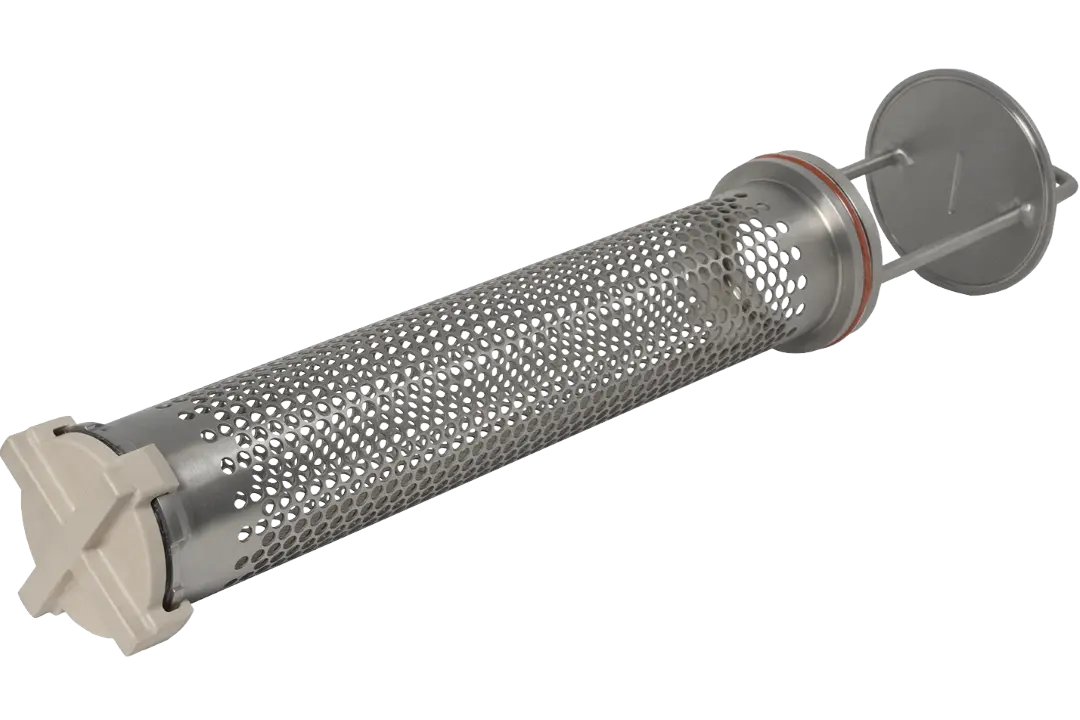

Tee-Line

Strainers

Protect your pump from foreign materials.

Easy to remove with low pressure drop.

Optional alignment pin available.

Y-Strainers

Designed to fit into tight spaces.

Utilizes few components for easy maintenance.

Multiple sizes and options available.

Basket

Strainers

Strain particulates out of high-volume systems.

Pressure tested & rated for high pressures.

Filter bags are available for finer straining.

Magnetic Trap

Strainers

Capture metal particulates with one solutions.

Adds minimal pressure drop.

Easily retrofittable to select strainers.

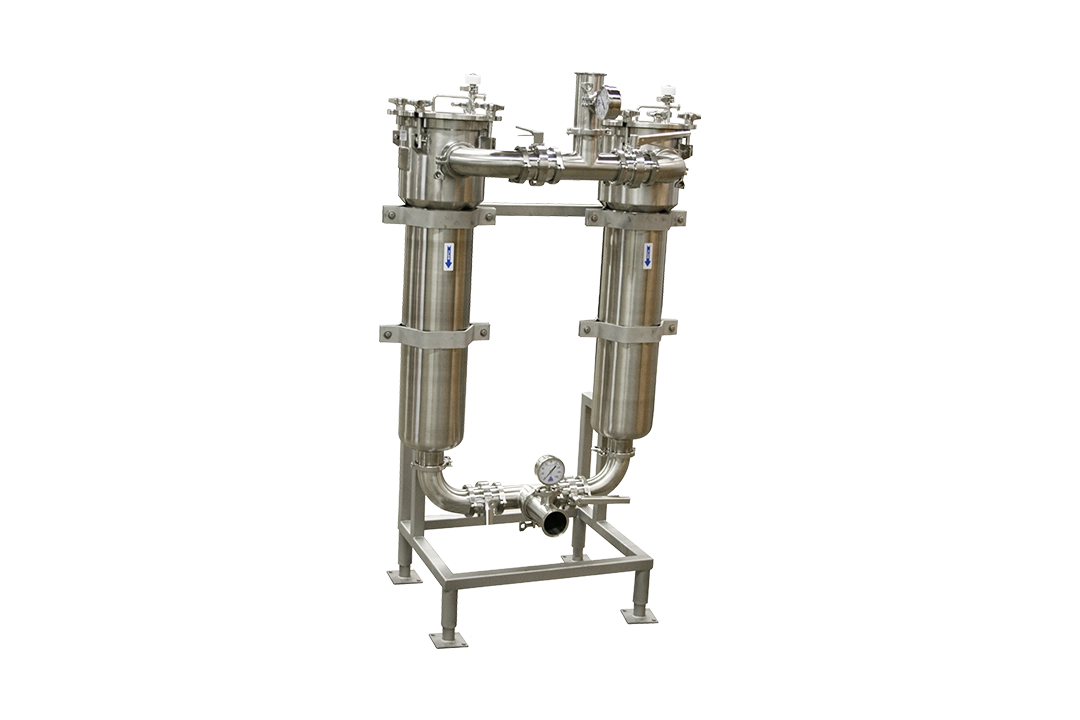

Multi-Strainer Assemblies

Reduce system downtime.

Manual & air operated options available.

Customize to a fully automated system.