Process Tanks

Tanks Designed for your Process, engineered

and fabricated in Wisconsin for a quick delivery.

Process Tanks

Tanks Designed for Your Process – Quick to Deliver

Sani-Matic has manufactured high quality tanks for sanitary and hygienic industries for decades. Our tanks can be designed and manufactured to meet specific industry standards upon request.

All Sani-Matic standard tanks, from 135 gallons up to 1,075 gallons, are manufactured in Sun Prairie, WI – this and stocked tank heads allow for quick turnaround times for high-quality tanks. Tanks can be made for various processes like CIP, Process, Holding, Surge, Mixing, and more. With a variety of standard sized tanks that can be customized with various features, Sani-Matic tanks will be sure to fit your process needs.

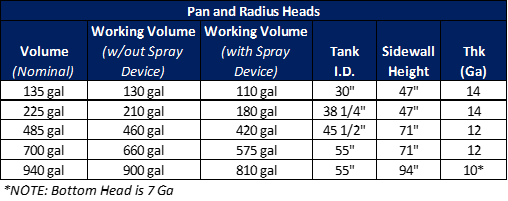

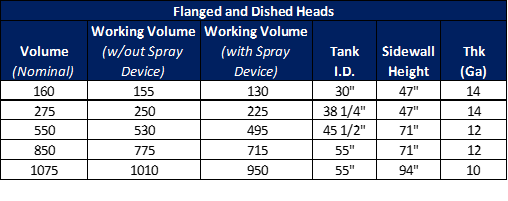

Standard food and beverage grade tanks are detailed below and available in two tank head variations – Pan & Radius Heads or Flanged & Dished Heads.

Resources

View brochures, manuals, technical datasheets, or watch videos for this product.

Articles

Read articles written by industry leaders to share their expertise and recommendations.

Product Resources

Literature

Videos

Product Details

Standard Features

○ 304ss Wetted Surfaces

○ 32 Ra µin ID Wetted Surfaces

○ ID Welds Color Cleaned

○ OD Welds Color Cleaned or Bead Blasted

○ Non-Sealing lift off cover

○ Heavy duty 304 stainless steel tubular or pipe legs

○ Sanitary tri-clamp type ports

Standard Process Tank Sizes

Standard food and beverage grade tanks are detailed below and available in two tank head variations – Pan & Radius Heads or Flanged & Dished Heads. The tank heads listed below are our standard sizes. Custom sizes are available upon request.

Custom Options

○ 316Lss Wetted Surfaces

○ 25 or 20 Ra µin ID Wetted Surfaces

○ ID Welds Ground & Polished

○ OD Welds Ground & Polished

○ Gasketed Manway (for tanks with spray devices)

○ Passivation

○ Material Test Reports (MTRs)

○ Adjustable tank feet

○ Insulated sidewalls

○ Anti-siphon for water inlet

○ Anti-vortex device

○ Spray devices and supply tubes

○ Other ports types (beveled, flanged, NPT, etc.)

○ Sidewall overflow or center skimmer overflow

○ Vents – mushroom or gooseneck

See us at IBIE - North Hall Booth #5655 | Sep 14-17, 2025 - Las Vegas, NV

See us at IBIE - North Hall Booth #5655 | Sep 14-17, 2025 - Las Vegas, NV