Clean-In-

Place (CIP)

Systems

From the standard 1 tank CIP Mini, to

customized CIP Systems to meet your exact

process needs, partner with the industry

leader in CIP.

Clean-In-Place (CIP) Systems

Designed for Your Application to Provide Reliable, Consistent Cleaning

Clean-In-Place (CIP) systems are automated systems used to clean the interior surfaces of food and beverage process pipes, processing vessels, tanks, spiral freezers, mixers, blenders, homogenizers, roasters and associated fittings, without disassembling the process. Thorough, repeatable in-place cleaning is critical to the quality of your product, the safety of consumers—and your bottom line.

Sani-Matic CIP Systems are engineered to your specific plant application, layout and utility requirements for effective and efficient sanitary process equipment cleaning. Our application-specific CIP design and sizing ensures sufficient flow. As a result, appropriate pressure is available to thoroughly remove residue, rinse effectively, shorten cycle times and promote worker safety.

Our in-house automation programming experts design each CIP program to optimize cycle times that get you back into production faster, while reducing chemicals, water use and operating costs.

Sani-Matic CIP Systems are sanitary and can be engineered to meet 3-A standards.

Literature

View & download our latest manuals, technical datasheets, catalogs & more.

Articles

Read articles written by industry leaders to share their expertise and recommendations.

Solutions We Provide

CIP Mini

Compact, portable, and cost effective.

Clean process tanks up to 11′ in diameter.

Clean process lines up to 3″ in diameter.

CIP Systems

Custom engineered to your specifications.

Fully automated and customized controls.

Able to meet FSMA, HACCP, & 3-A guidelines.

Sanitary Dryer L

Standard Dry-In-Place (DIP) skidded system.

Dry sanitary process lines & small equipment.

Integrate with automated CIP or standalone.

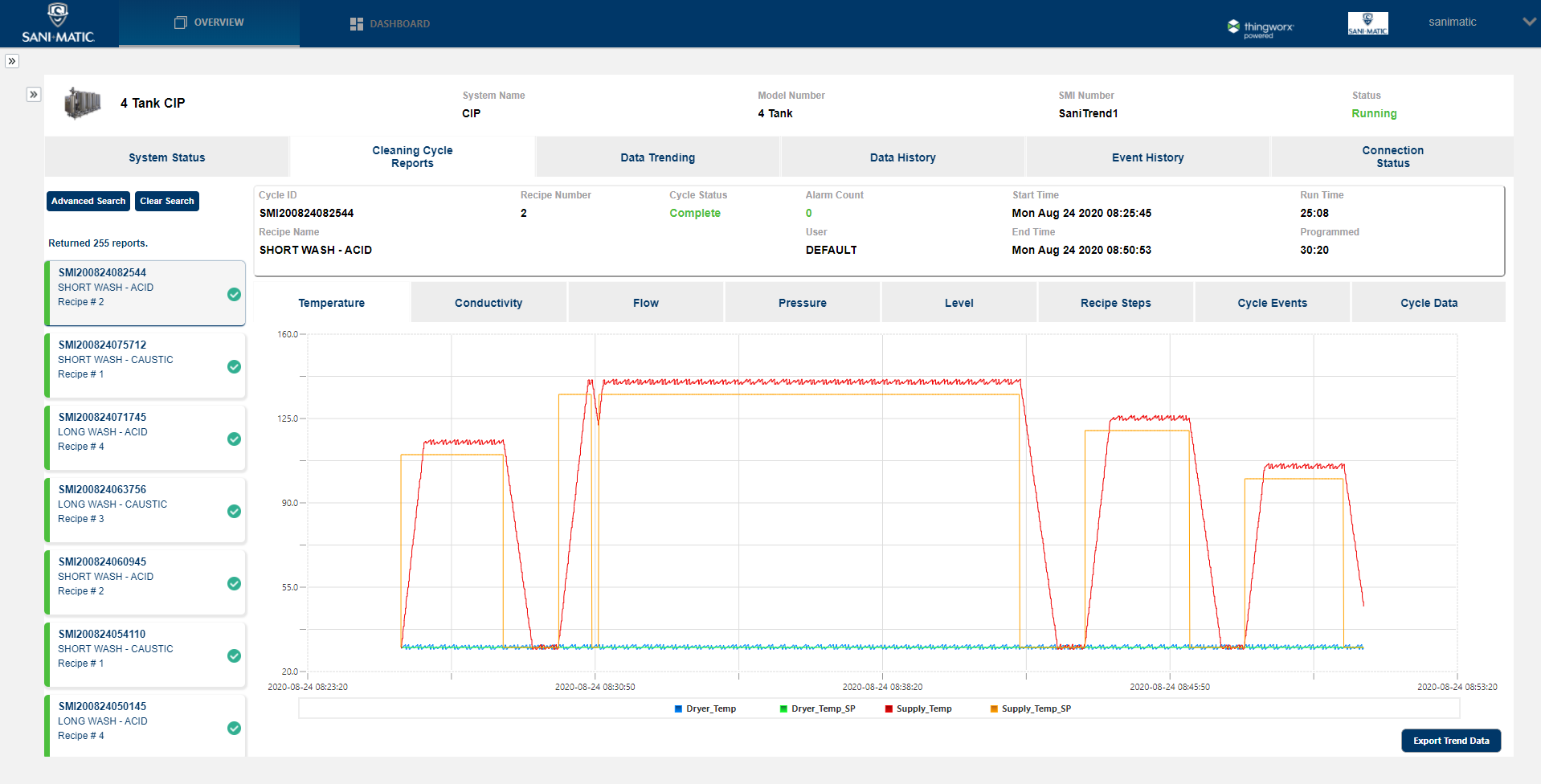

Automated Electronic CIP/COP

Data Recording, OEE, & More