Vat

Washers

Thoroughly Clean Vats, V-mag Buggies,

Bins, and Carts

Vat Washers

Thoroughly Clean Vats, V-mag Buggies, Bins and Carts

Many food manufacturers manually clean large product containers, such as vats or buggies, which requires a significant amount of time, water, chemicals and labor—an expensive process.

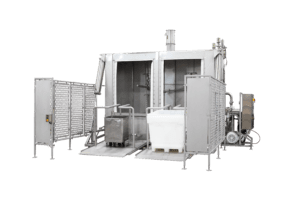

Sani-Matic’s automated Vat Washers are designed to thoroughly, and more efficiently, clean all product contact surfaces, as well as the exterior surfaces of large vats, bins, plastic combos and V-mag buggies.

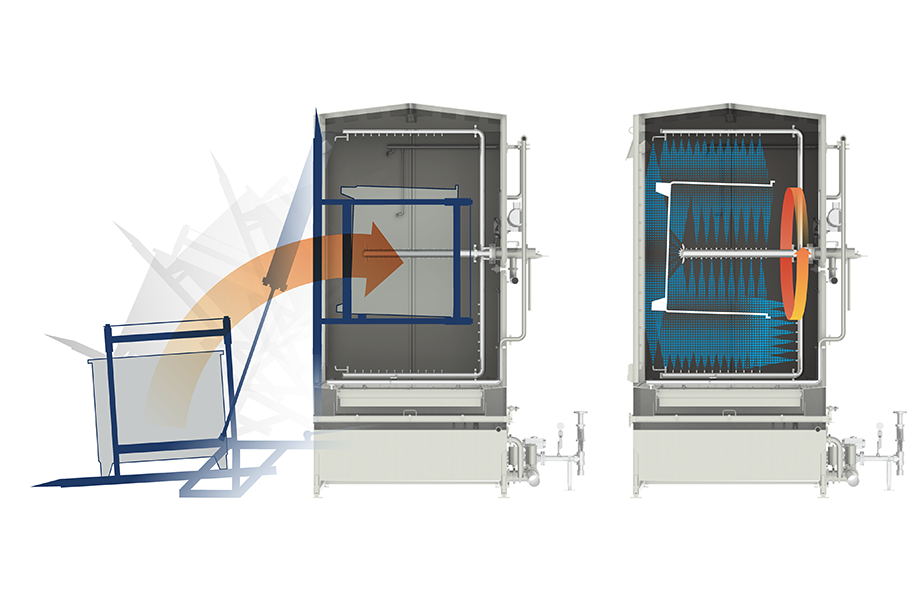

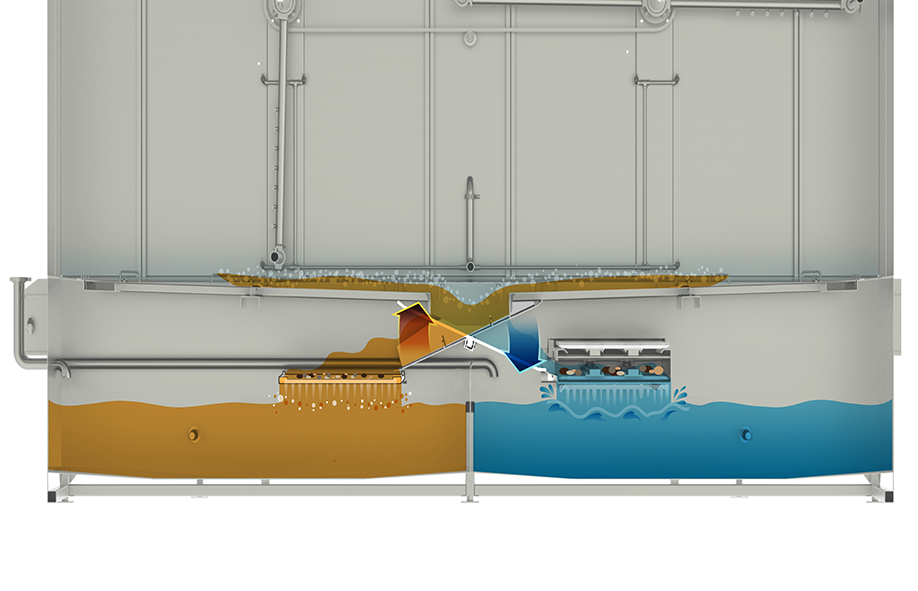

The containers are loaded onto an inverting door carriage and lifted into the cabinet where a high-impact rotating spray manifold ensures consistent, full-coverage cleaning. The Vat Washer’s unique dual reservoir design utilizes a pre-rinse process to conserve detergent, water and utilities.

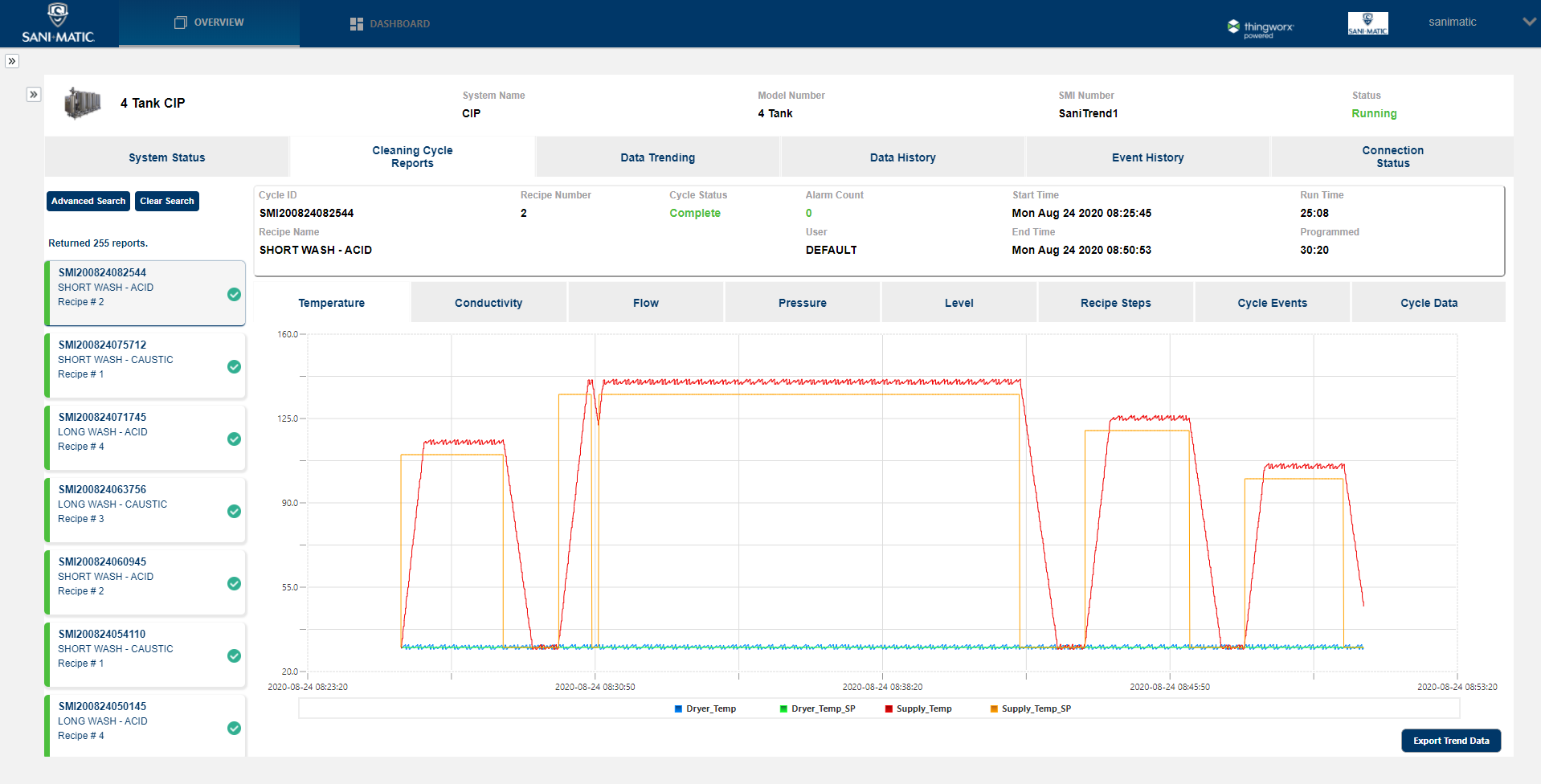

SaniTrend® Cloud or SaniTrend Local software packages are available as options, which enables fully automated reporting functionality, helping to meet FSMA reporting requirements for recording on cleaning & sanitation processes. SaniTrend Cloud’s online functionality also offers additional system insights including Overall Equipment Effectiveness (OEE) trending, live dashboards, preventive maintenance trackers, event notifications, and more.

Resources

View brochures, manuals, technical datasheets, or watch videos for this product.

Articles

Read articles written by industry leaders to share their expertise and recommendations.

Product Resources

Literature

Videos

Product Details

Standard Features

○ Single- and dual-position washers

○ Three- to five-minute typical cycle time

○ Stainless steel construction

○ Door carriage with hold downs and ramp for floor loading

○ Gear driven spray manifolds

○ High-impact, 360° spray nozzles including directional sprays to the bottom of vats and buggies

○ Two-stage solution-straining system with removable elements

○ Pre-piped centrifugal supply pump

○ Automatic temperature and water level controls with alarm and shutdown

○ Direct steam injection heating system

○ PLC controls with control interface and indicator lights

○ Automatic final rinse control

How it Works

Vat is inverted greater than 90° for complete cleaning coverage. Rotating spray arm provides high-pressure spray of vat’s interior and exterior.

Separate solution and pre-rinse reservoirs save chemicals. Diverter plate provides automated reservoir selection.

Custom Options

○ Automatic detergent injections/concentration control

○ Automatic sanitizer injection system

○ Custom door fixture to accommodate buggies, totes and conveyors

○ Blow-off dryer system

○ Motor starter/disconnect with cabinet-mounted enclosure

○ Electric immersion or steam coil assembly heating

○ Conveyorized strainer

○ Exhaust fan

Automated Electronic CIP/COP

Data Recording, OEE, & More