As concerns for food safety grow, so does the demand for effective tank cleaning equipment for food grade bulk transport. Whether a hauler is transporting liquid milk, juice, or syrup, a clean and sanitary transportation method is necessary for business success and the health of the community.

There are many regulations and guidelines for cleaning and sanitizing food grade tankers. For example, milk tank trucks that transport “Grade A” milk products must be cleaned at a permitted milk plant, receiving/transfer station or truck cleaning facility. According to the FDA’s Pasteurized Milk Ordinance (PMO), most facilities require a tag [1], or record, from a truck wash to verify tanks have been cleaned and sanitized before picking up the next product load. The FDA outlines similar guidelines for the transport of juice concentrates. [2]

When guidelines aren’t followed, and tanks aren’t properly cleaned and sanitized, the following problems may occur:

- Bacterial growth

- Allergen cross-contamination

- Degraded product integrity

- Failed inspections

That is why ensuring a complete clean is critical. And, although tanks may be cleaned manually, a drop-in spray device driven by a clean-in-place (CIP) or mechanical system provides a more consistent, reliable clean.

The Sani-Matic team’s expertise spans both sanitary components and process cleaning equipment. This depth of knowledge provides food grade transport customers the right tank cleaning equipment solution, whether it is a drop-in spray device or a drop-in spray device integrated with a CIP system.

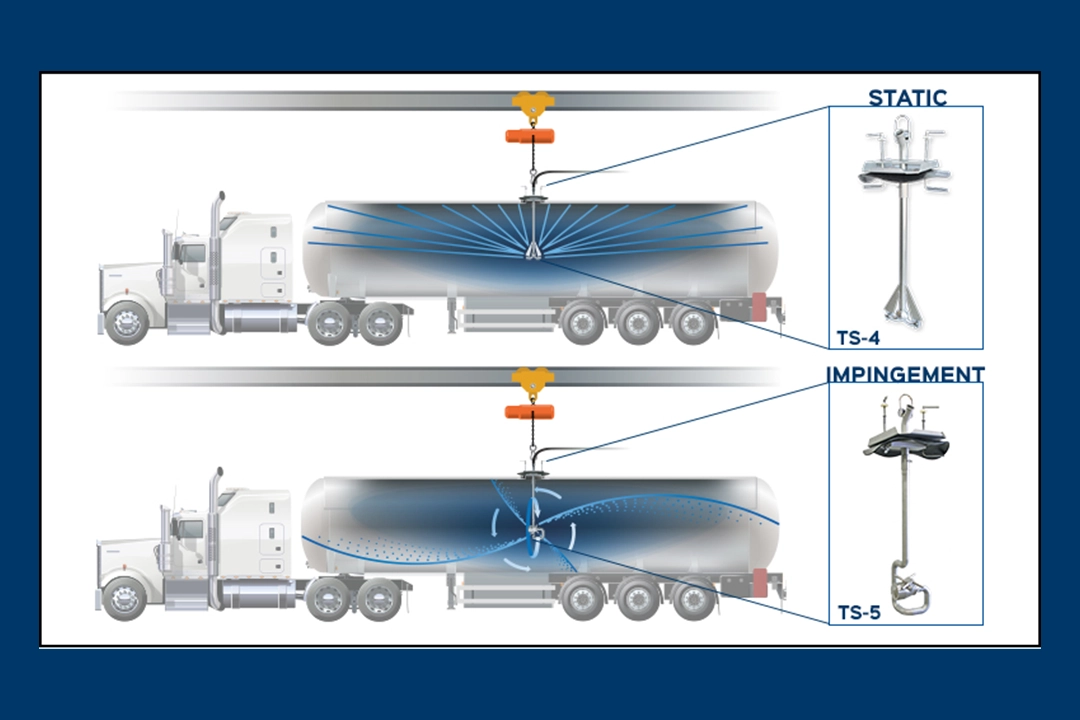

Sani-Matic provides two styles of drop-in spray devices designed specifically for cleaning food grade tanks. Both provide efficient, high-impact cleaning and increased productivity through fast cycle times.

Choosing the right tank cleaning equipment

The drop-in style TS-4 Tanker Spray Washer thoroughly cleans tankers up to 44 feet in length with a center-positioned spray ball and two, high-impact jet nozzles that provide a top-to-bottom spray pattern. The top of the tanker is sprayed directly with solution, which then cascades down the sides, removing soil. Its two multi-bore jet nozzles reach all product contact surfaces.

According to Sani-Matic Mechanical Designer Brian Schaal, “Anything that is water soluble can be cleaned with chemical, heat and water using the static TS-4 Tanker Spray Washer.”

The Sani-Matic TS-5, ideal for cleaning tanks up to 50 feet, uses a rotation impingement drop-in style spray device. Its S-shaped manifold spray nozzle rotates 360 degrees allowing direct impingement and cleaning solution delivery to all contact surfaces inside the tank. High-pressure nozzles provide the reach needed to clean longer tankers.

“When cleaning tougher soil loads or longer tanks, the TS-5 is recommended,” Schaal added. “The impingement spray may take several minutes longer than the TS-4 to reach and clean all the tank surfaces, but it is better able to tackle harder-to-clean areas and soils.”

CIP: the driver of the tanker’s spray device

Although the spray device dictates a lot of what happens during the clean-in-place process, the system that drives the device is also very important.

When designing a CIP system for bulk transport applications, Sani-Matic’s engineering and design teams dive deep into the application to understand the required chemistry, the necessary flow rate, and whether a two- or three-tank setup is needed to thoroughly clean a tanker—and get it back on the road quickly.

“The goal is to help customers boost production capacity while ensuring a safe and consistent clean,” stated Schaal. “When a truck can get back on the road quickly for its next delivery, and it is completely clean, we’ve done our job.”