There are a variety of spray ball types available to clean process vessels or other applications, but how do you choose the right one? It starts by understanding several factors including soil type, available flow rates, the size and makeup of the vessel to clean, and available ports or connection types.

Understanding Spray Balls and Spray Ball Types

Before diving into which spray ball type is the best fit for a clean-in-place (CIP) or clean-out-of-place (COP) application, consider the following:

- Drill Pattern. Spray ball drill patterns depend on a spray ball’s placement, surface area coverage requirements, and obstructions. See Table 1 for standard spray ball patterns ranging from 90- to 360-degree coverage.

- Ball Diameter. Ball diameters typically range from 1.25″ to 4″.

- Connection Size. Connection size may range from 0.5″ to 2.5″ and determines the maximum flow delivered through a spray ball with acceptable pressure drops. For example, a spray ball with a 0.5″ connection can only deliver a flow rate up to 12 gpm, whereas a connection size of 2.5″ can deliver a flow rate up to 400 gpm lending itself to clean a much larger vessel.

- Connection Style. A slip collar is a standard connection. Other connection styles include butt weld, flare (no connection), tri-clamp, half coupling, and pipe nipple. The half coupling and pipe nipple options are not 3-A compliant, all other connection styles are 3-A compliant.

- Flow (gpm). A minimum flow rate of 3 gpm for every foot of tank circumference is required to provide enough flow for cleaning coverage.

- Pressure (psi). 25 psi is the standard design flow rate if not specified by the user. The maximum pressure for custom spray balls is 70 psi. Spray atomization occurs above this pressure.

- Finish (Microinch Ra). Sani-Matic’s standard finish is 32 μin Ra/150 Grit and can be customized to 15 μin Ra/240 Grit to meet a variety of industry standards.

- Finish Options. Electropolish can be added to any finish.

- Spray Ball Types. Spherical, Tangential or Spray Bubble.

Digging Deep into Standard Drill Patterns

Sani-Matic’s Lead Components Designer Brian Schaal explained when choosing certain spray ball types and standard drill patterns it is important to consider where the spray ball is placed and what needs to be cleaned.

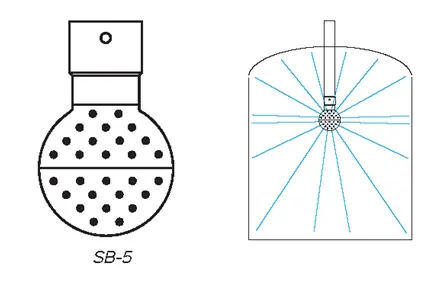

SB-5 | The SB-5 is intended for spray coverage that reaches all directions. It is the most common drill pattern. |

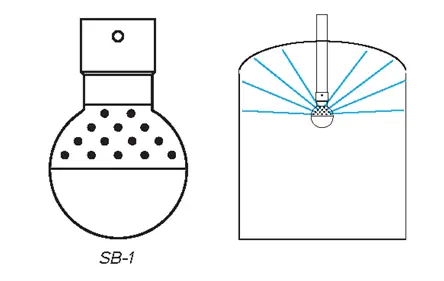

SB-1 | The SB-1 spray pattern is the second most popular pattern. It is used when only the top half of a vessel needs cleaning. It is inserted from the top of the vessel. |

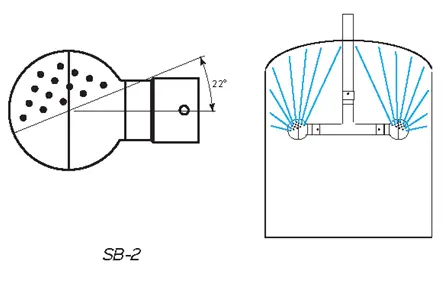

SB-2 | An SB-2 spray ball’s drill pattern is set 22° off horizontal to be a more efficient spray pattern when mounted horizontally on a double-ball tee. The drill pattern and double-ball tee are used together for full coverage of the tank head when equipment such as agitators, baffles, dip tubes, level sensors, level switches are present. |

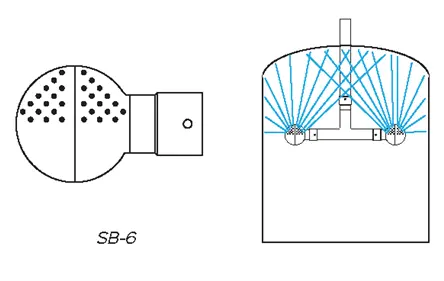

SB-6 | The SB-6 is a general spray pattern to provide upward or downward spray when mounted horizontally in a side port or when using a double-ball tee. It provides a truer 180° spray coverage than the SB-2. |

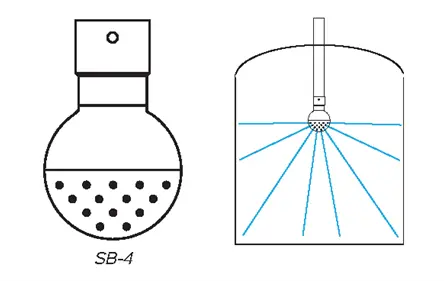

SB-4 | The SB-4 pattern can be inserted through various ports. For example, it could be inserted through the side of the tank and aimed at an agitator, from the bottom of the tank to spray upward, or inserted from the top of the tank to spray downward. This pattern targets half of a vessel’s cleaning area. |

Spray Ball Types: Which Type is Right for What Process?

Each market, process, and application has unique sanitary process cleaning needs. Consider the below information when choosing spray ball types.

Spherical Spray Balls. Versatile, Affordable, and Dependable.

Spherical spray balls are the most common spray ball type used in a variety of food & beverage applications. Available in 1.25″ to 4.0″ sizes, spherical spray balls can be easily drilled using common drill patterns and are easily customizable to various flow rates and other drill patterns when needed.

“Spherical spray balls are ideal for standard patterns and are a great option for more common applications like CIP tanks, mixing tanks and other horizontal and vertical cylindrical tanks we frequently see,” said Senior Product Manager Pete Barrie.

“There is one limitation to the spherical design,” Schaal pointed out. “And, that is a limitation with the degree of upward spray. Even with a 360-degree spray pattern, the upward spray coverage is slightly limited by the spherical structure. When that limitation affects a proper clean, we look to the tangential spray ball to achieve a full 360 degrees of spray coverage.”

Tangential Spray Balls. When Full Upward Spray is Required.

Tangential spray balls feature a flat top design, making them ideal for applications where full upward spray is required.

“We have more spray coverage flexibility using the tangential design,” Schaal explained. “They are predominantly used for directionally drilled patterns or custom pharmaceutical grade spray assemblies.”

“Also, when dealing with process contact surfaces with limited access points, obstructions or unique applications, directionally drilled tangential spray balls are the right solution,” added Barrie.

The primary limitation of Sani-Matic tangential spray balls is size. We only have them available in 2.5″ diameter and require a minimum port size of 3.0″ for welded assemblies.

Spray Bubble Spray Balls. When Space Constraints Cramp Your Clean.

While spray bubbles aren’t as common, they are ideal for applications where space is limited.

“The size-on-size spray connection is perfect for equipment with complex interiors such as ductwork, at the end of elbow assemblies, or lower-side ports aiming up at an agitator. It’s a great solution for non-standard applications with space-constraints,” explained Schaal.

Like spherical spray balls, spray bubbles have a limited range of drilling. However, unlike spherical options, spray bubbles can achieve the full 90 degrees of drilling when used with 1.5″ bubble hemisphere.

Spray Coverage Expertise.

Whether manufacturing food, beverage, or pharmaceutical products, Sani-Matic has the expertise to discuss various spray ball types and which is right for your application including additional ball diameters, connection sizes, finishes, and passivation.