CIP cleaning, also referred to as Clean-In-Place cleaning, is a procedure of cleaning interior product contact surfaces such as process pipes, vessels and equipment, without disassembly. Typical food and beverage applications cleaned using an automated CIP system are product transfer lines, processing tanks, homogenizers, mixers, blenders and fillers.

In contrast, Cleaning-Out-of-Place (COP) is a method used when parts cannot be cleaned-in-place and must be disassembled from the process. Typical process parts cleaned-out-of-place in parts washers and cabinet washers include hoses, clamps, fittings, scale buckets and other disassembled process components.

Whether CIP cleaning or cleaning-out-of-place, to achieve a sanitary clean, the basic cleaning principles of TACT—Time, Action, Chemical and Temperature—must be understood. These cleaning principles were introduced in 1959 by Chemical Engineer Herbert Sinner. He wrote an educational book regarding automated washing machines that targeted housewives. He posited the four cleaning factors, Time, Action, Chemical and Temperature, define the result of the cleaning process. (These factors are represented in Sinner’s Circle, see Figure 1.)

Automated cleaning systems have advanced significantly since 1959, but the cleaning principles of TACT remain the same. By understanding TACT and how specific plant processes affect it, Sani-Matic designs and engineers effective and efficient cleaning systems.

Where to Start When Considering CIP Cleaning?

Chris Kressner, lead project engineer for food & beverage, explained, “There are many considerations when designing a CIP cleaning system, but first, we need to understand what you are cleaning so we can properly apply TACT to the system design.”

“Liquid-soluble product is certainly easier to clean, but even with liquids you have variations. Tomato juice and orange juice have solids in them, so that’s tougher to clean than a sport drink. When the focus is cleaning dairy product lines, it’s important to keep in mind the possibility for bacterial growth versus a carbonated beverage which has lower pH and higher acidity decreasing the chance for contamination,” he said.

“For solids, CIP system design will vary depending upon the soil’s shape, size, load, and surface adherence of the particles. These all impact what we recommend,” added Kressner.

CIP Cleaning With TACT Principles in Mind

Once the product and process parts to be cleaned are clearly defined, the time, action, chemicals and temperature needed to provide a complete clean can be determined.

“Cleaning a dairy process such as a cold ice cream line may require more time to get the solution to the right temperature. You also need to run several chemicals in a cycle such as a caustic wash to remove dairy proteins and fats, an acid wash to remove the milk stone, and a sanitizer because dairy is so conducive to bacterial growth,” explained Kressner.

Pete Barrie, Sani-Matic’s product manager, said designing a system with the right action, or turbulence, to clean is critical.

“As we design a CIP cleaning system, we need to look at the process line size, distance from the process to the desired location of the CIP system, tank or equipment size and spray devices to determine the appropriate pump size. Minimum recommended line flow velocities for CIP are at least five feet per second. That flow rate generates enough turbulence to clean out short branches in a line to avoid dead legs. In addition to line flow velocity, other factors should be taken into consideration to avoid dead legs such as branch orientation, soil levels, and process conditions.” said Barrie.

Sani-Matic’s expert automation programming team assesses each of these considerations and develops recipes and setpoints for optimized CIP cleaning cycle results.

Other CIP Design Features to Contemplate: Two Tanks or Not Two Tanks, That is the Question

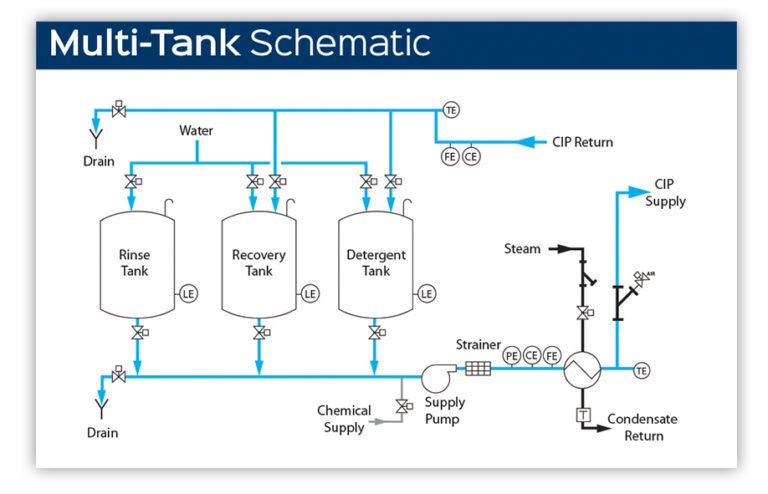

Single-tank, two-tank, multi-tank and multi-circuit designs are all options when building a CIP cleaning system. Some systems may require multiple tanks to avoid allergen cross-contamination or improve sustainability efforts by capturing the cycle’s final rinse water. Other processes can increase production capacity with a multi-circuit system, essentially giving customers the ability to clean multiple processes and products at the same time.

“When operating a single-tank system, you have to wait for that one tank to fill and drain for each step in a cycle. Adding a second tank dedicated to chemical allows for reuse of that chemical, and a third tank allows for a rinse recovery step to capture rinse water from a previous cycle to be reused in the next cycle’s pre-rinse step,” explained Kressner. (See Figure 2.)

Making the Investment Pay Off

Determining the right investment in a CIP system also greatly depends upon budget pressure, Barrie explained. More tanks designed into a system means more upfront capital cost, but it also increases production capacity.

“ROI on a CIP system often takes just one or two years,” Barrie said. “Some of our customers have production hours that run into tens of thousands of dollars. Saving them 15 minutes of cleaning time each week can create tremendous positive results.”