UltraFlow ®

Portable CIP Systems with a Small Footprint

and High-Impact Clean

UltraFlow ®

Portable CIP Systems with a Small Footprint and High-Impact Clean

As many pharmaceutical and biotechnology industry manufacturers turn to more flexible facilities with limited floor space, limited water and drain utilities, and no permanent supply and return lines, a flexible Clean-In-Place (CIP) solution is needed.

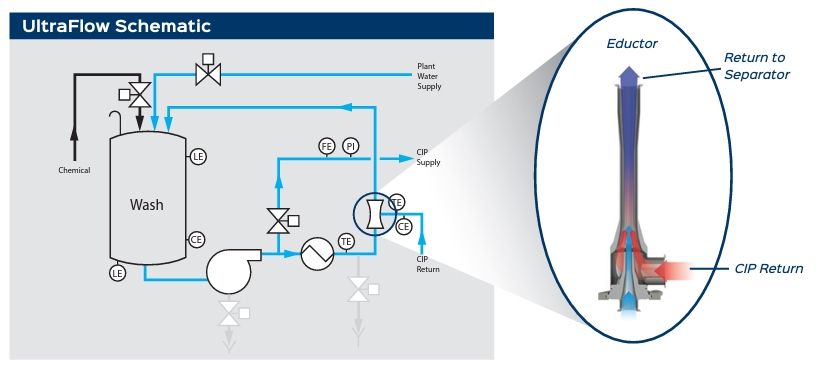

The Sani-Matic UltraFlow is a self-contained, compact, and portable system programmed to accommodate a variety of recirculated CIP applications. It returns solutions with entrained air to accommodate vessels with low and restricted outlets.

The UltraFlow is available in two models, the UltraFlow 45 and UltraFlow 110. Both models have a small footprint and maintain a wide operating range:

The UltraFlow 45 cleans tank diameters up to 4.5 feet and process lines with diameters up to 2” using a CIP flow rate of 2-45 gpm at 50 psi. Its dimensions are 68” L x 24” W x 74” H (height may vary depending on options).

The UltraFlow 110 cleans tank diameters up to 10’ and process line diameters up to 3” using a flow rate of 5-110 gpm at 60 psi. Its dimensions are 74″ L x 33″ W x 80” H (height may vary depending on options).

The system’s high-turbulence flow self-cleans the unit as it progresses through the cycle and removes solution buildup in the surge tank reducing the amount of time, water, and chemicals needed for a complete clean.

The UltraFlow has many unique features and options making it flexible and capable of providing a repeatable, documentable clean while meeting cGMP and ASME BPE standards.

Wondering if the UltraFlow can work for your process? Contact us and we’ll help find the solution for your critical cleaning challenge.

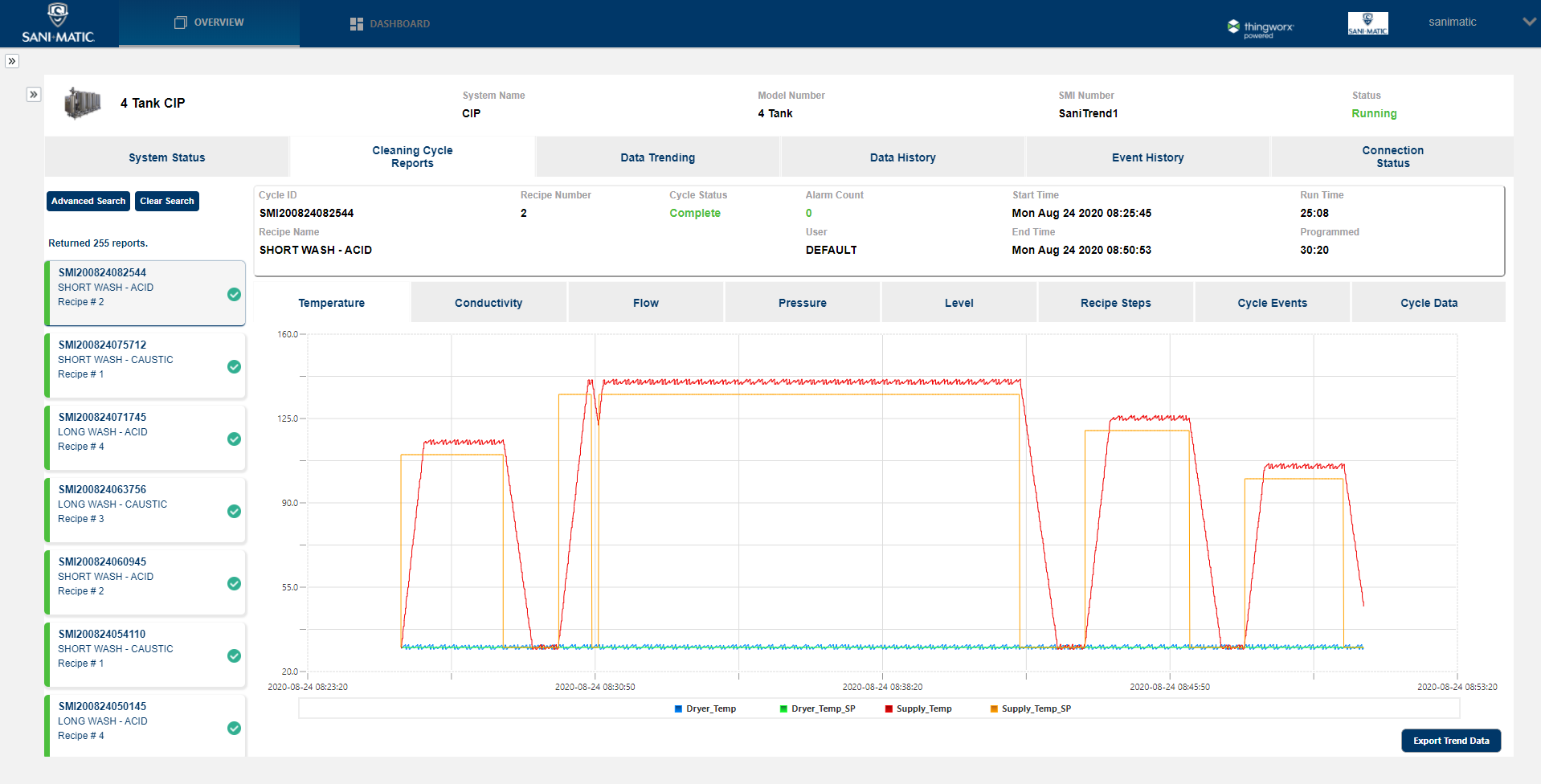

Available with SaniTrend ® Cloud CR Insights+ for Data Acquisition

SaniTrend Cloud provides automated, secure data acquisition and reporting of critical cleaning cycle information. The SaniTrend Cloud CR Insights+ tier is available as an option that is fully 21 CFR Part 11 Compliant, helping you meet reporting requirements for recording on cleaning processes. SaniTrend Cloud’s online functionality also offers additional system insights including Overall Equipment Effectiveness (OEE) trending, live dashboards, preventive maintenance trackers, event notifications, and more.

Resources

View brochures, manuals, technical datasheets, or watch videos for this product.

Articles

Read articles written by industry leaders to share their expertise and recommendations.

Product Resources

Literature

Videos

Product Details

Standard Features

○ A single centrifugal CIP supply pump

○ Modulating diaphragm control valves to set cleaning circuit flow rates and to control the rate of discharge to drain

○ Two chemical delivery systems comprised of pneumatic diaphragm pumps, removable chemical reservoirs

○ Chemical conductivity, proof of rinse conductivity

○ Supply and return temperature sensors

○ Electric flow-through heater

○ Discharge pressure gauge

○ Low friction, non-marking casters

○ Wetted surface: 316Lss, 25 µin Ra

○ Non-wetted surface: 304ss, 32 µin Ra

○ UL listed, 304 stainless steel, NEMA 4X enclosure

○ Allen-Bradley CompactLogix PLC

○ Allen-Bradley PanelView Plus HMI

○ Ethernet communication

○ 40 customizable cleaning cycle programs

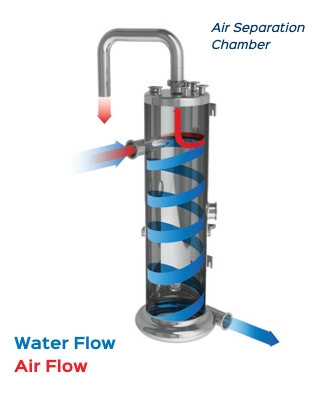

○ Eductor return system

How it Works

Custom Options

○ Vent filter assembly

○ Pressure transmitter

○ Mass flow meter

○ Fixed position leveling feet

○ Frame weld finish upgrade

○ Sanitary flex hose package

○ Piping insulation

○ Fixed position seismic zone calculations

○ Passivation

○ Larger electric heater

○ Wetted Surface: 15µin Ra Electropolish (EP) finish

○ Allen-Bradley PanelView Plus 1000

○ Report ticket printer

○ Stainless steel motor

○ Shell and tube heat exchanger

○ Air blow manifold

○ Chemical reservoir low level switches

○ CIP supply routing valves

○ Water connection bleed valves

○ Sample valve

Automated Electronic CIP/COP

Data Recording, OEE, & More