Boosted

Pressure

Systems

High-Impact Cleaning for

Hard-to-Clean Areas.

Boosted Pressure Systems

High-Impact Cleaning for Hard-to-Clean Areas

Automated sanitary process cleaning equipment provides a great number of benefits, but there are often areas such as walls, floors, platforms and difficult-to-disassemble equipment that simply cannot be cleaned with automated equipment such as CIP or COP systems.

When you cannot perform traditional CIP or COP on your equipment, Sani-Matic’s Boosted Pressure Systems are designed to provide water at an elevated (boosted) pressure (typically around 300 psig) to Washdown Equipment located throughout your plant for operators to perform thorough cleaning of open plant areas.

Although often times Boosted Pressure systems feed Washdown Equipment for manual cleaning, Sani-Matic also is design and manufacture feed fixed spray devices fed by customized Boosted Pressure systems that provide more CIP-like automated rinse, foam and sanitize processes of complex equipment, conveyors, and dryers.

Literature

View & download our latest manuals, technical datasheets, catalogs & more.

Articles

Read articles written by industry leaders to share their expertise and recommendations.

Product Resources

Literature

Videos

Product Details

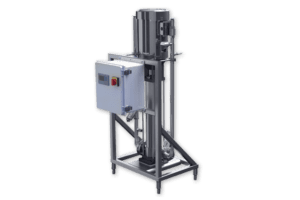

Floor Mounted Features

○ Multiple standard model sizes:

● Booster 1 (one user maximum)

● Booster 1X (one user maximum)*

● Booster 4 (four user maximum)

● Booster 8 (eight user maximum)

○ Multi-stage, self-priming

centrifugal pump sized to serve the number of simultaneous operators

○ Pump discharge pressure gauge

○ Pressure switch disables system at low psi and temperature switch disables system at high temperature (adjustable set point)

○ Flow switch automatically enables booster pump when needed. Disables pump at completion

○ Manual water supply inlet isolation ball valve

○ 200 mesh water supply strainer and 304ss wetted surfaces

*Note: Booster 1X provides higher GPM and psi than Booster 1

Custom Options

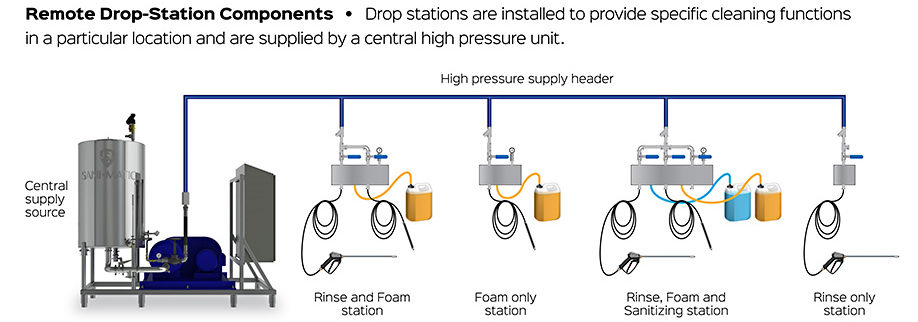

○ Washdown Stations available in:

● Rinse, Foam, or Sanitize Only

● Rinse / Foam

● Foam / Sanitize

● Rinse / Foam / Sanitize

○ Automatic temperature and water level controls with alarm and shutdown

○ In-Tank steam heating – direct steam injection

Automated Electronic CIP/COP

Data Recording, OEE, & More