Paper based Chart Recorders are used in the food & beverage industry and other applications where continuous records of scaled or analog type data is recorded. The technology dates back to the 19th century, with a chart recorder for environmental monitoring being issued a patent back in 1915.

If you are new to the industry, an assumption may be made that chart recorders are no longer used. However, many applications in the industry, from process data recording (e.g., pasteurization, product temperature) to cleaning activities (e.g., Clean-In-Place (CIP) or Clean-Out-of-Place (COP)) still utilize this outdated paper based technology.

All of a sudden, you’re asking yourself some good questions. Why do people still use chart recorders? What technologies exist out there to replace them? What are the challenges of trying to automate this process? This article explores common challenges that are faced when trying to automate manual processes, with a focus on chart recorders. To address these challenges, the Digital Process Recorder (DPR) (powered by SaniTrend® Cloud) solution is reviewed against the efforts required for automation. The DPR is an electronic data recorder with online software access through the SaniTrend® Cloud portal that can replace paper-based chart recorders.

Paper Chart Recorder

Leaving the Chart Recorder Challenge #1 – Automation is EXPENSIVE

A common objection to automating manual processes are that the cost of the technology to the solution is expensive. While the cost for the automated technology is often higher than the manual solution, the actual return on investment (ROI) is not taken into account.

Generally, when it comes to chart recorders, there are several areas where the daily operation of the chart recorder itself is very time and labor intensive – which is inherently costly! For example:

- Chart Recorders require people to install, annotate, transport, review, and store the paper documents.

- Chart Recorders are not efficient when it comes to accessing the data. Being paper based requires those who need to see the data to be at the paper chart.

- Chart Recorders require continuous maintenance costs – paper charts, pens, and other mechanical parts.

Electronic solutions like the DPR automatically captures and stores the needed data points. The data is then easily reviewed in the cloud where it is more detailed, accurate, available, visible, and filterable than any paper record. After review of how automation can transform data recording processes, the cost for the automated technology can easily be justified when looking at operational efficiency gains.

Leaving the Chart Recorder Challenge #2 – Automation is COMPLEX

Automation can be complex, and trying to develop your own electronic, digital, paperless chart recorder solution is probably out of the question. The next step is to investigate existing solutions out there. Many automation projects can seem daunting and hard to start. Who do I partner with? What products and solutions are available?

Unquestionably, larger system wide or plant-wide automation projects and the discovery and execution phases are typically very complex. Luckily, the chart recorder application has simple “drop-in” solutions like DPR. The control panel for this cloud-based solution is swapped with the chart recorder. 4-20 mA signal wiring and control power can be switched. Finally, bring in an internet connection to the panel, and you’re off and running.

Digital Process Recorder (DPR)

Additionally, executing a project to increase automation of your plant will make you more comfortable with future automation projects. The key to growth through automation is to tackle projects and gain more confidence over time.

Leaving the Chart Recorder Challenge #3 – Automation is TIME CONSUMING

Arguments can be made that automation is time consuming. This refers to both the time to implement the automated solution, and time for new users to learn how to use the new solution. In the above complexity challenge, it was discussed how the DPR is easily dropped in to replace a chart recorder. Typically, any time to execute the solution is spent on the upfront scope work. This includes looking for solutions and answering the “will this new solution or product work” question. The DPR solution is built specifically for replacement of manual process chart recorders. This makes the work of finding the solution easier with a standard product for replacement.

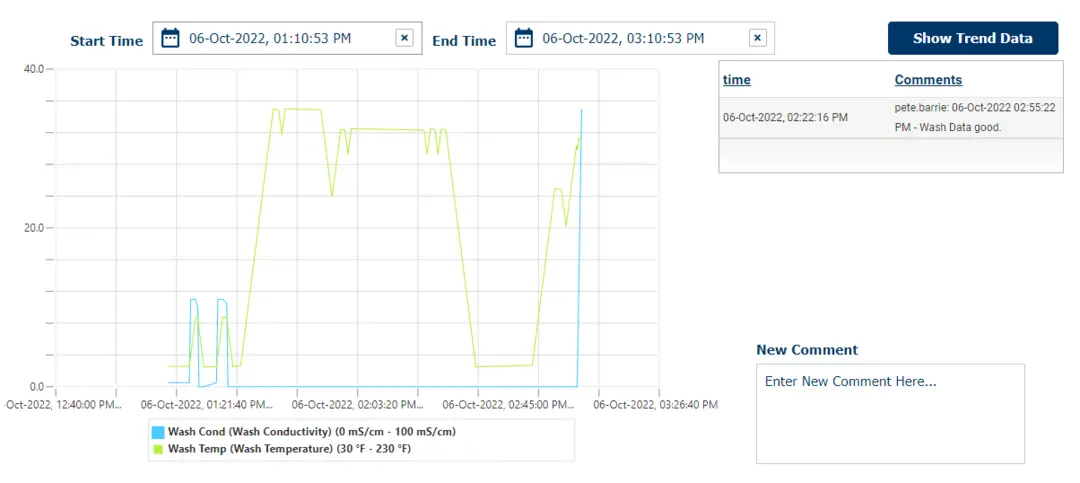

The other time investment is learning the operation of the software or user interface (UI) of the automation program. SaniTrend® Cloud’s online UI is intuitive, simple, and easy to pickup. The data is searchable, filterable by date and time, and securely accessible from anyone with web browser.

SaniTrend Cloud® – User Interface (UI)

All of a sudden, through implementation of the right solution, automation can occur quickly and the benefits can be achieved without an investment of a large amount of time.

Leaving the Chart Recorder Challenge #4 – Automation Solutions are INACCESSIBLE

Automated solutions appear advantageous, but can seem inaccessible for the average company. How should the automation process start? What parts of the process can be automated? These questions are sometimes tough to figure out.

Similarly to the complexity discussion, automating a chart recorder data collection system can be made easy and accessible to the average sanitary processing facility. This is not and does not need to be a massive, plant-wide automation project. The DPR integration into the existing process or cleaning operation is easy and simple.

Authored By Pete Barrie | Sani-Matic | Product Management Director