Clean-Out-

of-Place

(COP)

Systems

Designed for Your Application to Provide

Reliable, Consistent Cleaning.

Clean-Out-of-Place (COP) Systems

“COP” Doesn’t Just Mean a COP Parts Washer Anymore

COP Parts Washers are cost efficient and do a great job when trying to eliminate some of your manual washdown cleaning processes. They can tackle a variety of parts cleaning applications as well. In addition to COP Parts Washers, there are many more automated COP options today.

Automated Cabinet Washers – More Advanced COP Technology

Do you use a dishwasher at home to clean your dishes? If so, you’ve invested in a more automated process to clean. Automated Cabinet Washers, like our SaniCab® P and PC – act in a similar fashion – capable of fully automating the rinse, washing, and drying of process parts.

Vat/Buggy, Product Carrier, and Stick Washers for Particular Applications

While the SaniCab® cabinet washers are capable of cleaning many small to medium sized parts on custom designed racks, Sani-Matic also offers more application-specific washers. Vat and Buggy Washers tackle 1-2 vats or buggies per wash cycle, Product Carrier Washers wash 1 to 10+ racks or product trees at a time, and Stick Washers can handle up to 1,000 product or meat sticks in an hour.

Tunnel Washers for High-Volume Throughput

If you have many of similar parts like pallets, trays, totes, or other items – a conveyorized tunnel washer can provide high-volume cleaning. The loading and unloading of the parts can be done manually, or it can be automated through integration into conveyor feed systems or through other automated material handling methods.

Literature

View & download our latest manuals, technical datasheets, catalogs & more.

Articles

Read articles written by industry leaders to share their expertise and recommendations.

A New Brand of Cleaning Equipment for the Baking and Meat & Poultry Industries

Solutions We Provide

COP

Parts Washers

Uses high-velocity jets to clean parts.

Ideal for hoses, fittings, & other process parts.

Many options & customizations available.

CyClean™ 35

Parts Washers

CleanWorx™ Brand Parts Washer for COP

Simplified Sales Process, Quick Delivery

Standard, Cost-Effective Equipment

SaniCab® P

Cabinet Washers

Fully automated and extremely versatile.

Cleaning cycles as short as 10 minutes.

Many options & customizations available.

SaniCab® PC

Cabinet Washers

Designed to NSF/ANSI/3-A SSI 14159-1.

Meets stricter sanitary & hygienic standards.

Many options & customizations available.

Vat

Washers

Clean large containers such as vats or buggies.

Dual reservoirs reduce chemical consumption.

Vats inverted into cabinet for a complete clean.

Product Carrier Washers

Ideal for large racks, trees, cages and trucks.

Pit or floor mounted options.

Accommodates overhead rail or roll-in racks.

Tunnel

Washers

High-volume throughputs.

Manual or automated material load/unload.

Customized zones per application.

Stick

Washers

Safe, reliable way to clean product sticks.

Save time – clean up to 1,000 sticks per hour.

Requires minimal floor space.

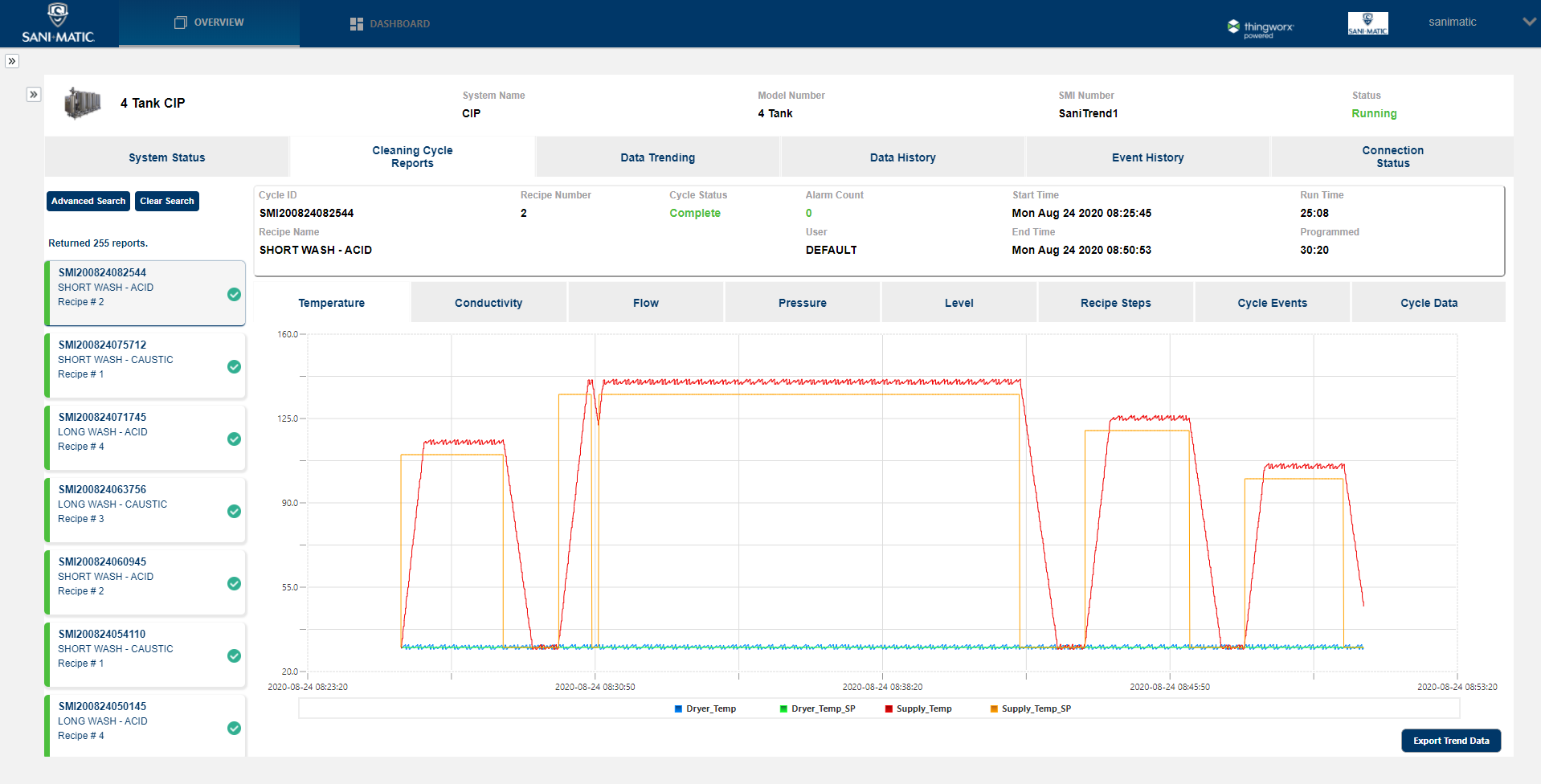

Automated Electronic CIP/COP

Data Recording, OEE, & More