Bio-Pharm:

Clean-Out-of-Place

(COP) Systems

Repeatable, Validatable COP Results

Bio-Pharm: Clean-Out-of-Place (COP) Systems

Trusted by Industry Leaders

Some of the most recognized brands in the world trust Sani-Matic with their toughest critical cleaning challenges. Because they put customer and product safety at the top of their list, they turn to Sani-Matic for hygienic cleaning solutions and Cleaning Confidence.

All Sani-Matic bio-pharm cleaning equipment for the pharmaceutical, biotech, nutraceutical and personal care industries meets cGMP and ASME BPE standards, as well as individual safety and manufacturing standards, for repeatable and validatable results.

Whether you’re looking for automated cabinet washers, agitation immersion washers, or ultrasonic immersion washers, Sani-Matic has the GMP cleaning system to meet your COP requirements.

Bio-Pharm Customer Feedback

“Sani-Matic made their product adapt to our needs instead of making our process adapt to their product…they were very flexible throughout the process.”

– Global Generics Pharmaceutical Company

Literature

View & download our latest manuals, technical datasheets, catalogs & more.

Articles

Read articles written by industry leaders to share their expertise and recommendations.

Solutions We Provide

SaniCab® PC

Cabinet Washer

Designed to NSF/ANSI/3-A SSI 14159-1.

Meets stricter sanitary & hygienic standards.

Many options & customizations available.

PharmaCab® SP Cabinet Washer

Fully automated cleaning solutions.

Meets cGMP and ASME BPE standards.

Many options & customizations available.

PharmaCab® MP Cabinet Washer

Clean and dry an entire lab suite at once.

Supplied by an external CIP System.

Meets cGMP and ASME BPE standards.

PharmaCab® LP Cabinet Washer

Ideal for Intermediate Bulk Containers (IBCs).

Supplied by an external CIP System.

Meets cGMP and ASME BPE standards.

Immersion Parts Washers

Hygienic Designed Jet Manifolds.

Fully Automated operation.

Meets cGMP and ASME BPE standards.

The Sani-Matic

Factory Acceptance

Test

Have you ever experienced a FAT where the manufacturer was not prepared and everything went wrong and it left you feeling disappointed and frustrated?

We promise that feeling will NOT be your experience with Sani-Matic – from the technical preparation to the hospitality, you’ll leave never wanting to FAT anywhere else!

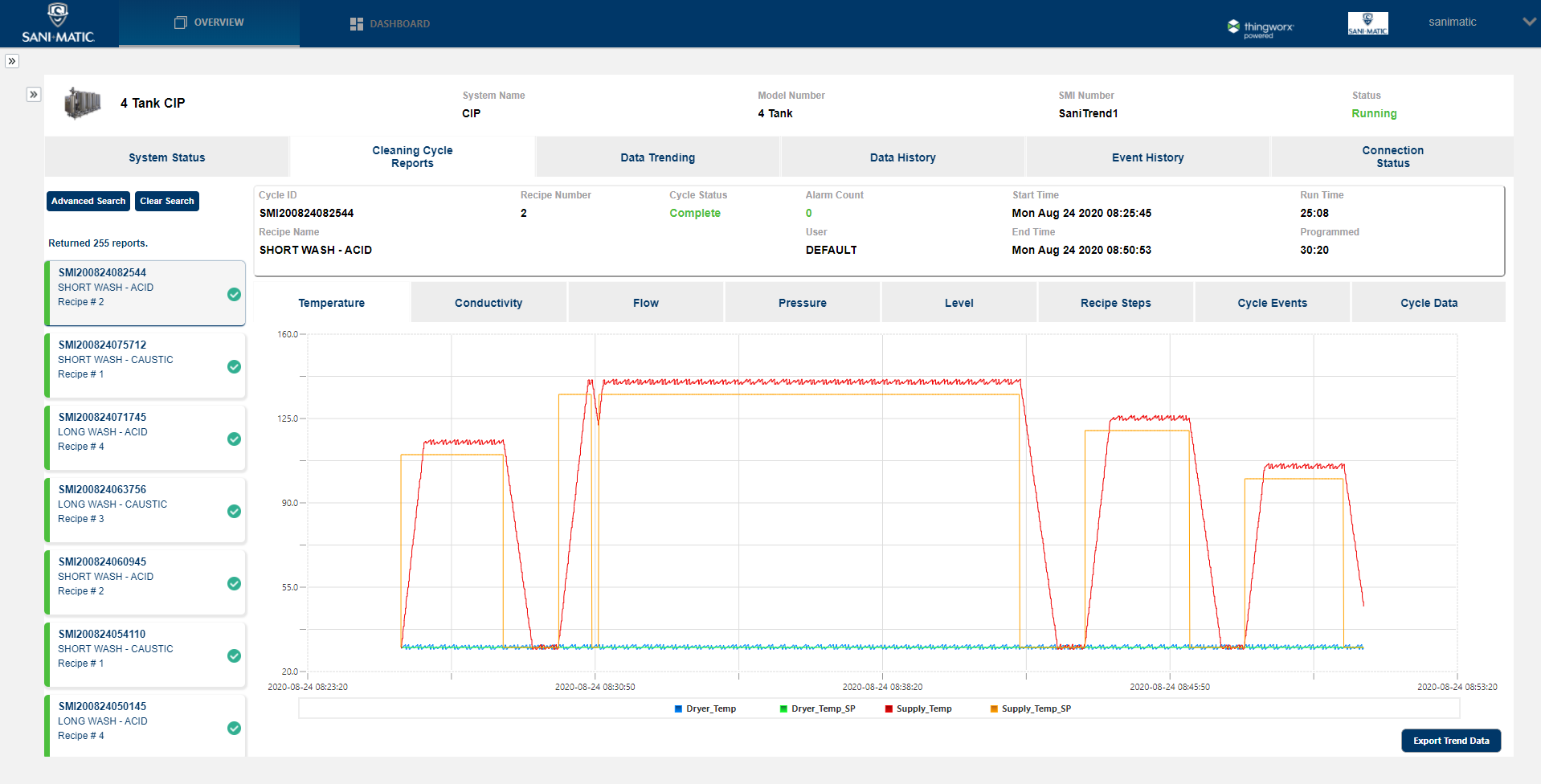

Automated Electronic CIP/COP

Data Recording, OEE, & More